Just an update and new photos. The tear down continues. Been some hick-ups, but nothing super major.

When I bought the machine, I checked the runout on both tables. There was a minimal variance of the .0002 in travel overall on the x-axis, and .0002 on the y-axis. When I tore everything down, both axis had been shimmed .0006.

1. The table had smooth free running travel with no binding end to end. So contemplating putting shims back in and running it that way for awhile.

2. Not sure what a regrind, scraping and flaking will run. No one locally , I feel I can trust. Reached out to a gentleman in Knoxville, that used to work at Oakridge and maintain their machines. Waiting to hear back from him.

Removing the power feed was a major obstacle in itself. At one time while moving the machine the lead screw got bent. The bearing was seized on the shaft. I had to break out a portable hydraulic press to get the power feed off. It was so bad ended up mushroom the end of the shaft.

You can see some of the variance in the shaft end here.

1. Went to pick up replacement that came with the machine, they tried to give me a 42" lead screw, they are looking for the correct one. That is how it goes.

2. May just end up going with the shorter lead screw, and more modern power feed. More decisions.

The check for the wear on the lead screws they seem fine, only a few spots over the entire length that varied more more than .0005. The lead screw nuts were a different story

The threads were flaring out on one end of both, and they were grimed and gunked up with all manner of crap.

This was late last night after wiping down 2 inches of axle grease caked on the outside.

Inside the knee was a mess. Apparently they thought oil fittings were grease fitting. It was like concrete to get some of it out.

This was after an hour of work, with degreaser and a scraper.

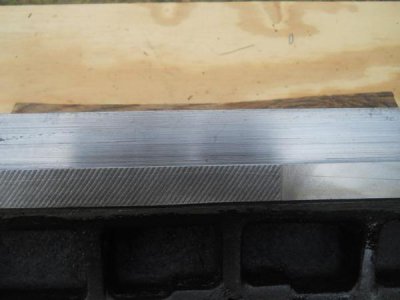

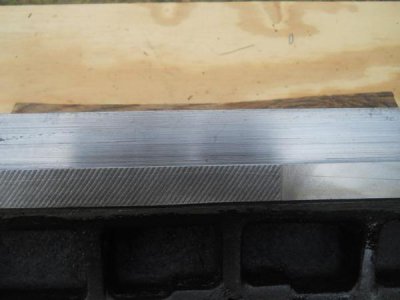

The scraping and flaking on the ways are non-existant, polished with some galling in places, but everything is smooth in its travel

Another major screw up to fix.

Worm gear damage

Screw is in great shape.

Bins of parts are soaking for cleaning. Table will go into tank for the last of the surface rust removal.

Hopefully will have the knee pulled today and tear down finished. Several friends stopped by to help last night. One in particular, likes to throw money around commented, " Why do all this, just go buy one ready to run." The other one I thought was going to smack him. Point blank told him " Because it is not in his nature, he likes to rebuild everything, and know what he has."

I probably could spend the bucks to get one in a lot better shape, and ready running. However, I am enjoying this to the last minute. Hurt like the dickens in my older age from the heavy work and lifting, but gives me focus.

On a happier note, I have another mill head waiting if I decide not to rebuild this one. It is a 63 model Bridgeport. Runs like a dream. Now if I could find a replacement door, for the one missing.

I have new high output led lights coming to repair the original, light that came with it. A late birthday gift/favor returned from a fellow boater I do work for that makes underwater LED lights.

Okay chime in with comments recommendations and the such.