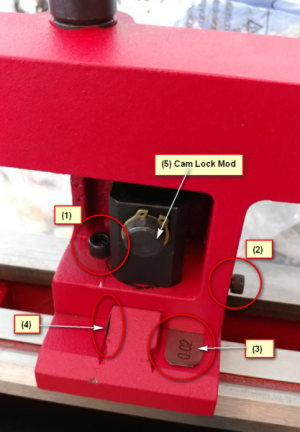

For any new folks, I wanted to share the mods I made to my Harbor Freight 7x12 Mini-Lathe tail stock.

I've referenced the item numbers in the attached photo to the text in this post.

(1) Overall I found the design for being able to adjust the tail stock alignment to the chuck to be very poor. I won't go into how to do the alignment since that is covered a lot already (just google). I used one live center and one dead center to do the alignment.

The basic problem is that the factory adjustment screw is on the bottom where you can't get to it...and you need to have the tail stock mounted to make the adjustments.

So what I did was drill 1/4 inch hole all the way through so the hole came out on the top side. This hole is threaded from the factory as a 5mm size. I found this size to be too 'weak' so I went with a 1/4 inch size. There is a slot on the bottom where a 1/4 inch square nut fit perfectly in the slot. So I could insert a new bolt from the top side and screw it into the nut on the bottom and have it grab so I could adjust and then lock the tail stock down solid. Item (2) has to be loose as well when making alignment adjustments.

So now I can adjust with the tail stock mounted and do this from the top side. A big improvement over the way the factory expects you to do the adjustments (if needed).

(2) I didn't like the screw driver screw that came from the factory and I didn't care for the size. However, to drill a larger (1/4 inch) hole would mean to go through a lot of metal, so I opted to just replace the screw with a hex head. This will allow me to lock this with more pressure than I could get with a screw driver.

I would like to say that I found drilling through item (1) all the way through was fairly easy, but the distance to drill through for item (2) is quite long so I opted not to do that.

(3) I had to shim to level the tail stock.

(4) Item (2) is not centered in the Y axis, so when I tightened in this screw, the whole tail stock wanted to turn CCW. This caused the live/dead centers to shift in the Y axis. To prevent this CCW turning I had to add about .030 thick shims where the arrow head is pointing to.

So the tail stock is now level and true and doesn't shift on me when I lock down items (1) and (2).

All in all, the adjustment design on the tail stock is very poor in my opinion from the factory.

(5) The last item is a Cam Lock mod that I did to remove having to use a wrench to lock and unlock the tail stock. I bought the Cam Lock Kit from the LittleMachineShop.com when I went out to their shop last week. They drilled the large, thick hole and installed the parts for me. It works very well and is fast to adjust and lock down. I highly recommend this mod.

My main purpose for visiting the LittleMachineShop.com facility was to use their hydraulic press to remove the ball bearings from the spindle box and press in new roller bearings.

I've referenced the item numbers in the attached photo to the text in this post.

(1) Overall I found the design for being able to adjust the tail stock alignment to the chuck to be very poor. I won't go into how to do the alignment since that is covered a lot already (just google). I used one live center and one dead center to do the alignment.

The basic problem is that the factory adjustment screw is on the bottom where you can't get to it...and you need to have the tail stock mounted to make the adjustments.

So what I did was drill 1/4 inch hole all the way through so the hole came out on the top side. This hole is threaded from the factory as a 5mm size. I found this size to be too 'weak' so I went with a 1/4 inch size. There is a slot on the bottom where a 1/4 inch square nut fit perfectly in the slot. So I could insert a new bolt from the top side and screw it into the nut on the bottom and have it grab so I could adjust and then lock the tail stock down solid. Item (2) has to be loose as well when making alignment adjustments.

So now I can adjust with the tail stock mounted and do this from the top side. A big improvement over the way the factory expects you to do the adjustments (if needed).

(2) I didn't like the screw driver screw that came from the factory and I didn't care for the size. However, to drill a larger (1/4 inch) hole would mean to go through a lot of metal, so I opted to just replace the screw with a hex head. This will allow me to lock this with more pressure than I could get with a screw driver.

I would like to say that I found drilling through item (1) all the way through was fairly easy, but the distance to drill through for item (2) is quite long so I opted not to do that.

(3) I had to shim to level the tail stock.

(4) Item (2) is not centered in the Y axis, so when I tightened in this screw, the whole tail stock wanted to turn CCW. This caused the live/dead centers to shift in the Y axis. To prevent this CCW turning I had to add about .030 thick shims where the arrow head is pointing to.

So the tail stock is now level and true and doesn't shift on me when I lock down items (1) and (2).

All in all, the adjustment design on the tail stock is very poor in my opinion from the factory.

(5) The last item is a Cam Lock mod that I did to remove having to use a wrench to lock and unlock the tail stock. I bought the Cam Lock Kit from the LittleMachineShop.com when I went out to their shop last week. They drilled the large, thick hole and installed the parts for me. It works very well and is fast to adjust and lock down. I highly recommend this mod.

My main purpose for visiting the LittleMachineShop.com facility was to use their hydraulic press to remove the ball bearings from the spindle box and press in new roller bearings.

Last edited: