- Joined

- Aug 8, 2017

- Messages

- 17

Hi y'all, I got my first lathe. It's pretty exciting for me but it's very basic, probably not too interesting for other people. It doesn't even have a chuck, just a faceplate and dead centers!

Like I said in my intro. post last week, I'm looking to get a real machine, like a Grizzly G4003 or a PM-1236. But, in the meantime, I found this lathe for free (no motor) on the Syracuse craigslist and I thought I could learn something about how to operate a lathe while I wait to get a real machine.

I took apart the carriage and tailstock, dunked everything in degreaser and ran every part through my new parts washer. I oiled everything, put it back together, and I don't have any parts left over, so that's good!

Side note: I wanted to replace a taper pin, then I looked up what an assortment of pins costs, and just reused it as is. The assortments don't even cover the really small pins like this machine has (0.090", size #5/0) so .. well I know this is going to be an expensive hobby!

The assortments don't even cover the really small pins like this machine has (0.090", size #5/0) so .. well I know this is going to be an expensive hobby!

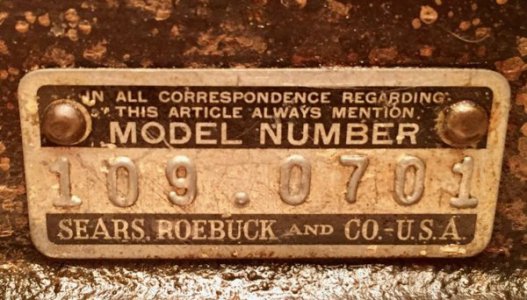

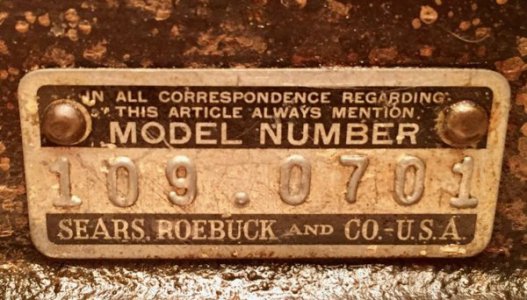

The lathe is at least as old as me because when I was a kid, Sears and Roebuck was already just called Sears.

I borrowed a 1/3 hp motor from my dad. I have a feeling it'll be enough to turn little stuff, but I don't know, what do you think?

It has a forward/reverse switch right on the motor, so that might come in handy.

Now I just need to mount everything to my bench. I have a belt, and both machines have cone pulleys .. so .. will the belt fit both? I don't know anything about belts. I probably need some advice about that.

Well, I hope that wasn't too boring. It's exciting for me. I've been watching machining videos on YT for at least a year, so I'm stoked to finally get a lathe to play with. Maybe you can relate to getting your first machine tool?

Like I said in my intro. post last week, I'm looking to get a real machine, like a Grizzly G4003 or a PM-1236. But, in the meantime, I found this lathe for free (no motor) on the Syracuse craigslist and I thought I could learn something about how to operate a lathe while I wait to get a real machine.

I took apart the carriage and tailstock, dunked everything in degreaser and ran every part through my new parts washer. I oiled everything, put it back together, and I don't have any parts left over, so that's good!

Side note: I wanted to replace a taper pin, then I looked up what an assortment of pins costs, and just reused it as is.

The lathe is at least as old as me because when I was a kid, Sears and Roebuck was already just called Sears.

I borrowed a 1/3 hp motor from my dad. I have a feeling it'll be enough to turn little stuff, but I don't know, what do you think?

It has a forward/reverse switch right on the motor, so that might come in handy.

Now I just need to mount everything to my bench. I have a belt, and both machines have cone pulleys .. so .. will the belt fit both? I don't know anything about belts. I probably need some advice about that.

Well, I hope that wasn't too boring. It's exciting for me. I've been watching machining videos on YT for at least a year, so I'm stoked to finally get a lathe to play with. Maybe you can relate to getting your first machine tool?

Also feel free to ask anyone here about the cost of this obsession, I mean hobby, seems expensive at times but for me at least the smile on my face and satisfaction of finishing a project big or small makes it worth it.

Also feel free to ask anyone here about the cost of this obsession, I mean hobby, seems expensive at times but for me at least the smile on my face and satisfaction of finishing a project big or small makes it worth it.