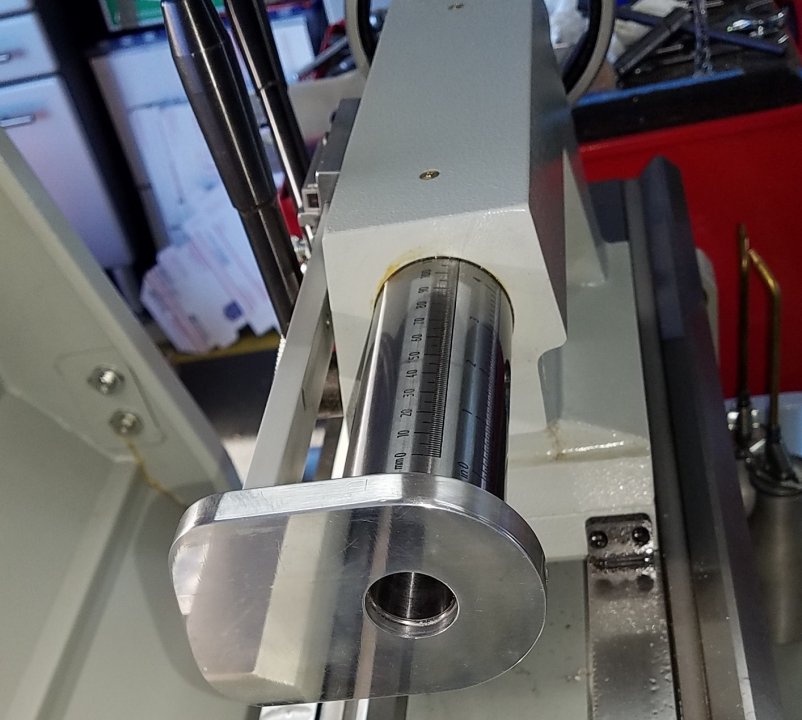

I had a solar powered Mitutoyo 6" caliper that had jacked up inside anvils. I don't remember where exactly they came from but were free. I must be fat and cause a solar eclipse because every time I tried to use them, I blocked the light and they would go blank. So I stole other ideas and put them to good use. Just a mount held on the tailstock by magnets which was machined from some junky 2" cold roll I dug out of the dumpster at work. The calipers are also held with the same 12mm magnets you can get at Lowes or Ace and I assume plenty of other places. The corner should have been 93 degrees instead of 92 degrees and if I ever get a piece of aluminum, I will probably remake the entire setup as I'm not thrilled with the finish but it works. It is also angled 30 degrees to read easier.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Cheap Tailstock DRO

- Thread starter Jason812

- Start date

I'm working on 3D printed mounts for the iGaging 6" DRO. The tailstock quill bracket uses M4 screws and nuts to tighten around the quill. The sensor is mounted with a 3D printed bracket using neodymium magnets. The digital readout uses one 1/4-20 bolt to fasten to a magnetic base. No drilling and tapping of the tailstock required. I'm swapping out the long USB cable the DRO is sold with for a short one. The iGaging DRO has the advantage of being able to set the DRO reading if you want. If you're interested, let me know. I'm considering printing and supply these for others if people are interested.I like that, I'm going to copy your idea, thanks!

This is for the PM-1340GT if it isn't clear, but it may also fit other tailstocks. The one in the picture above looks like my 1340. Here's a 3D model so you can see what it looks like. I'm waiting on the magnets to come in to complete it!

- Joined

- Oct 28, 2020

- Messages

- 542

How you you deal with the rotational play of the tail stock quill in this situation?I'm working on 3D printed mounts for the iGaging 6" DRO. The tailstock quill bracket uses M4 screws and nuts to tighten around the quill. The sensor is mounted with a 3D printed bracket using neodymium magnets. The digital readout uses one 1/4-20 bolt to fasten to a magnetic base. No drilling and tapping of the tailstock required. I'm swapping out the long USB cable the DRO is sold with for a short one. The iGaging DRO has the advantage of being able to set the DRO reading if you want. If you're interested, let me know. I'm considering printing and supply these for others if people are interested.

This is for the PM-1340GT if it isn't clear, but it may also fit other tailstocks. The one in the picture above looks like my 1340. Here's a 3D model so you can see what it looks like. I'm waiting on the magnets to come in to complete it!

View attachment 391594

- Joined

- Jun 10, 2019

- Messages

- 539

Can't speak to all lathes, but the TS on my G4003G will pop out MTs that have a tang at about the 1.25" mark. Even non-tang'ed MTs will pop at about 3/4". Its something that's always annoyed me because you loose about 1" of travel. But in any event: the design would work fine if your TS is similar.Also, seems like you cannot retract the quill fully to pop the Morse Taper out of battery, how do you deal with that?

If not: I'd imagine you'd have to extend the screw w/in the TS to pop out the MT earlier in the travel. Some MTs do have a threaded end and you can install a longer screw in the MT so it ejects earlier.

- Joined

- Jun 10, 2019

- Messages

- 539

Which model lathe?My Grizzly, the TS quill has to be retracted fully before it ejects the Morse taper.

- Joined

- Jun 12, 2014

- Messages

- 5,071

I did mount an Igaging Absolute on my 1340Gt many years ago, I put the display on an adjustable arm. You can get some interference of the bracket with the tailstock, so I eventually put a knurled locking knob so I could easily move the scale bracket to different positions so it would not interfere with the QCTP. On my current lathe the ram needs to come allmost all the way back to eject some MT3 holders, I had enough room on the backside of the tailstock to mount the scale head. The DRO scale mounting bracket is recessed and has two set screws to secure it to the ram. On the 1340GT you might want to mount the Igaging on the top, and possibly using neodymium magnets to secure it, although I secured mine with two small screws behind the reader and used small jacking screws in the corners for alignment.