- Joined

- Jun 22, 2012

- Messages

- 1,552

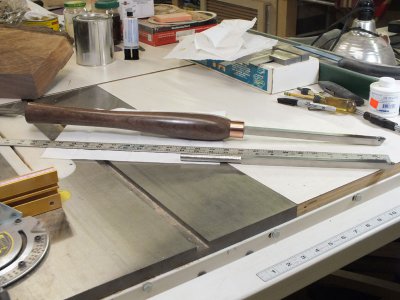

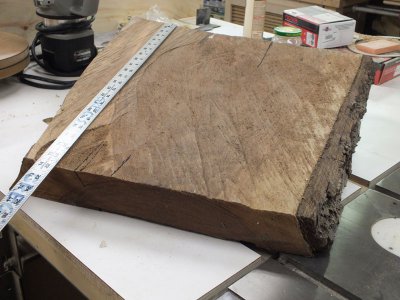

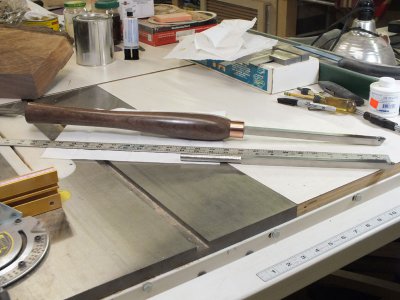

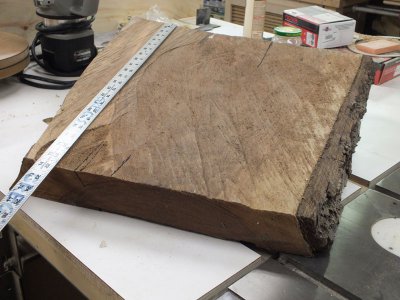

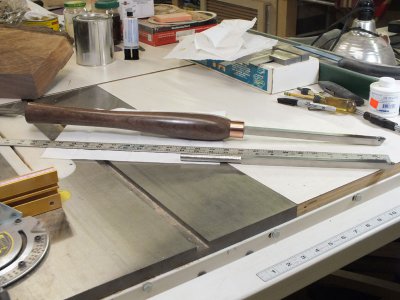

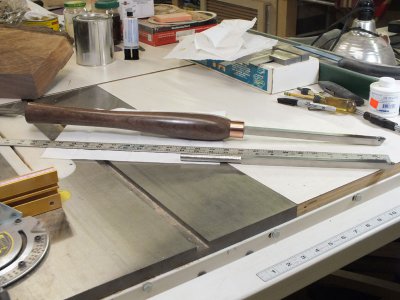

My chisels are made of 1/2" square 304 stainless steel. The tool working length is about 10" and the handle length is about 19". The handle was made from a slab of black walnut, the ferrule is 1" heavy wall copper pipe. The tool works excellent. Made a couple for friends too.

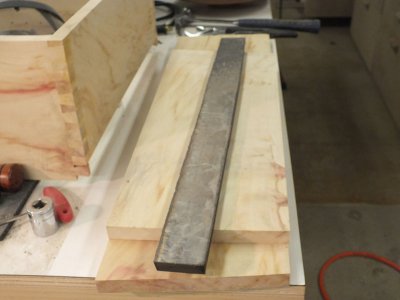

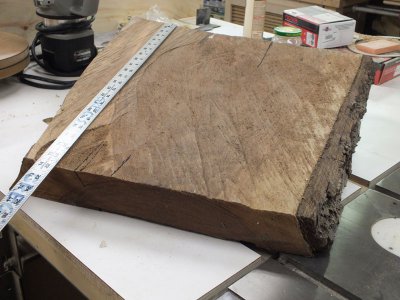

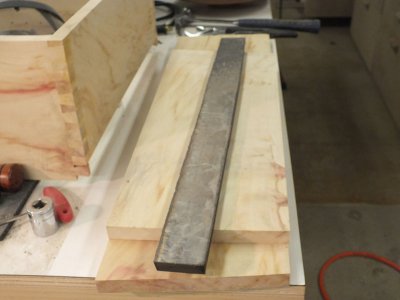

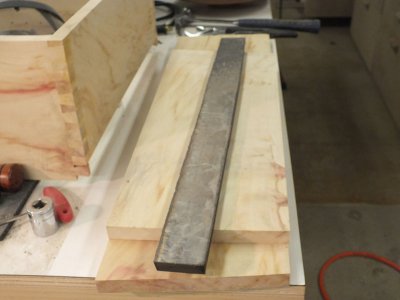

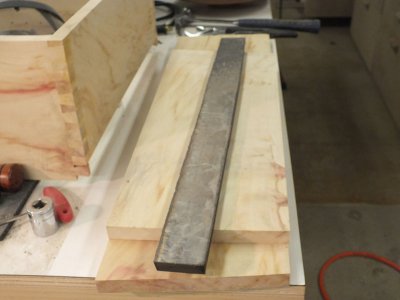

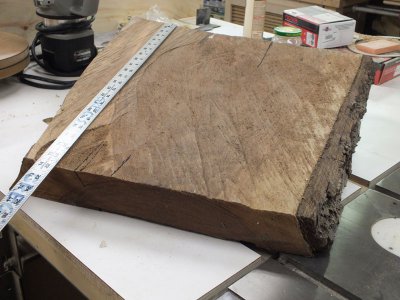

Then I got ambitious and made a hollowing chisel out of 1/2" 304 stainless steel plate. I had a shop cnc plasma cut the blank. Then I used a 4" flap grinder and file and sandpaper to smooth and contour the shape. There is not a sharp or square edge anywhere on this tool to catch on anything when turning. It takes me about 8 hours not counting the machining to make one of these. I can get to the bottom of about an 7" or 8" vessel with this tool. It works awesome as well. The handle was made from a piece of curly oak I saved from a firewood pile.

Then I got ambitious and made a hollowing chisel out of 1/2" 304 stainless steel plate. I had a shop cnc plasma cut the blank. Then I used a 4" flap grinder and file and sandpaper to smooth and contour the shape. There is not a sharp or square edge anywhere on this tool to catch on anything when turning. It takes me about 8 hours not counting the machining to make one of these. I can get to the bottom of about an 7" or 8" vessel with this tool. It works awesome as well. The handle was made from a piece of curly oak I saved from a firewood pile.