Well I decided to refresh the mill. Not going to be a rebuild per say. There are some broken things, its rusty, its worn but it should be a decent machine for a hobby. I bought this mill from a guy in Carrollton who was moving. Paid $300 for it. Im completely new to machining. This is a 1966 Bridgeport 1HP Series 1 mill.

Anyways, after lots of research, videos, etc... I took the plunge. Im not going to open the head as I checked the spindle runout was less than .001" in my indicator. I dont have a tenths indicator. The backlash on the x axis was something like .022", y was .027". There was quite a bit of play in the table with the y axis gib bottomed out. Im going to try and shim it. Here are a few pics from the breakdown.

The entire quill downfeed system was trouble. The clutch lever is broken, the other lever to engage is was broken. The pins and thread stop is all stuck. I tore it all apart yesterday and put it back together for now. Looks like someone tried to fix it before. Ordered parts

Started cleaning up all the rusty table end holder things and the knobs, dials, etc. Just using a fine wire brush on the drill press:

The knee handle and left table end were the worst but cleaned up well. I may polish them

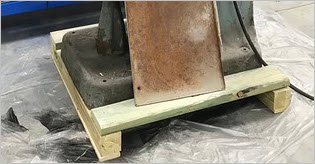

Mill table is going in a bath or vinegar to try and clean it up. I was thinking evaporust...but at $90/5 gallons and the box I built to soak it in is 15 gallons... Im going cheap:

The saddle will be next:

Dirty but very smooth: Im not going to mess with the mill knee.

And for the end of today... I decided to cut my nuts in half

Anyways, after lots of research, videos, etc... I took the plunge. Im not going to open the head as I checked the spindle runout was less than .001" in my indicator. I dont have a tenths indicator. The backlash on the x axis was something like .022", y was .027". There was quite a bit of play in the table with the y axis gib bottomed out. Im going to try and shim it. Here are a few pics from the breakdown.

The entire quill downfeed system was trouble. The clutch lever is broken, the other lever to engage is was broken. The pins and thread stop is all stuck. I tore it all apart yesterday and put it back together for now. Looks like someone tried to fix it before. Ordered parts

Started cleaning up all the rusty table end holder things and the knobs, dials, etc. Just using a fine wire brush on the drill press:

The knee handle and left table end were the worst but cleaned up well. I may polish them

Mill table is going in a bath or vinegar to try and clean it up. I was thinking evaporust...but at $90/5 gallons and the box I built to soak it in is 15 gallons... Im going cheap:

The saddle will be next:

Dirty but very smooth: Im not going to mess with the mill knee.

And for the end of today... I decided to cut my nuts in half