This is a long term tale with many false starts, revisions, and even some total stupidity. One nice thing about freescale building is no matter how many changes you make, it's still "right".

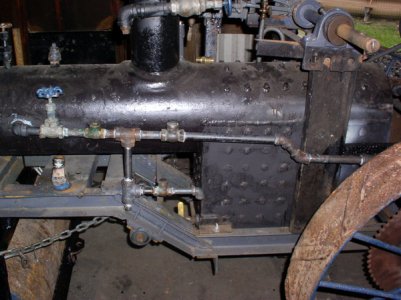

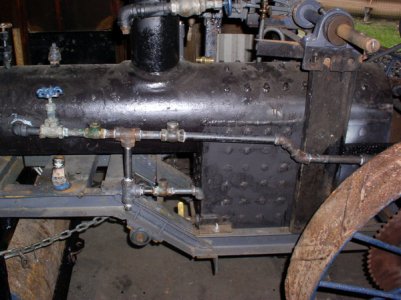

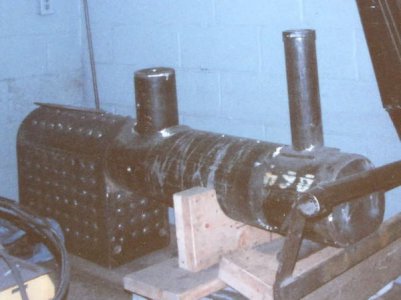

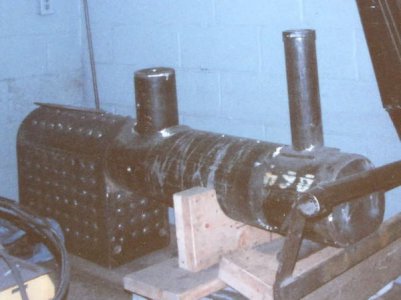

Way back in 1997, I decided my final project from welding school would be a miniature boiler. I spent a goodly chunk of change on materials that came with the ASME paperwork, got a set of 1993 ASME code books and did ALL the calculations - even the conflicting ones. Performed multiple destructive testing if EVERY joint set-up. AND passed my ASME welder testing. The result was a boiler the calculations said was good for 400psi (the minimum sheet thickness is .370!), but fit under EVERY part of Section I part PMB (100psi limit) Overkill? Not to the wonderful Communewealth of Pennsyltucky. They refuse to inspect it. The excuses keep changing. From, "I'm sure it's safe, but I'm not going to be the first guy to sign off on it." to "How do I know you did the calculations correctly?" to "The sheets aren't stamped with the paperwork numbers." (Btw MODEL boilers are NOT required to be stamped, as per part PMB).... Ohio OTOH doesn't bother anybody with barrels under 16". Since I can't fix bureaucratic stupid, when this is done, I'll just show it in Ohio and "T'ell wid" PA.

Anyway, the dimensions on the boiler are very close to 1/3 of my 25HP 20th Century (the barrel is 10" schedule 40, and 4 feet long the barrel of the 20th Century is 29" in diameter), but with a standard firebox (A full size Miller firebox is big enough of a maintenance headache!). I originally had a Carter steam car engine in mind and was going to make a model 20th Century. But the engine deal fell through, and never found a nearly complete Mason that I could afford.

Somewhere around '99 or Y2K I was at the Cabin Fever Expo in York, Pa as a vendor. I got a brief break and saw HALF of a Mason in the consignment area. At $800 it wasn't much of a "deal" so it was still there at the end of the show. But I decided to take a chance on it, anyway.

About 18 months later ANOTHER partial half Mason showed up on fleabay. Unfortunately, it was the same half. Fortunately, it had a complete Stephenson's reverse! I took off the reverse parts I needed off and resold the rest... for about $200 more than I paid - also thereby reducing the cost of MY engine to a less cringeworthy $600 in the process!

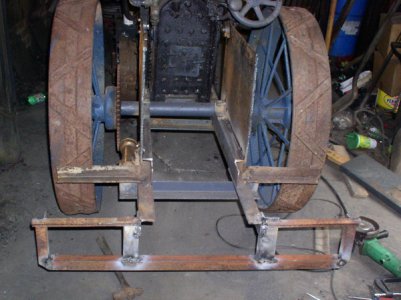

So now I had a boiler, and an engine. What I didn't have was a place to work, or money to spend. I was blindsided with a "trial" separation, then divorce papers soon after. Everything went into what I HOPED would be short term storage. But I was wrong. It wouldn't be until 2009 that I would again be in any position to return to it. That summer I happened to see an estate auction in the Farm and Dairy paper. It listed a BUNCH of old tractors and parts. I didn't have much money, but it sounded like a nice afternoon of free amusement anyway. In one of those seredipitous moments, I ended up coming home with this lump of "scrap" for the princely sum of $25

A roller it would be!

But it would still be another year, and yet another move, before anything much got underway. Since I hadn't done any extra calculations to mount stuff directly to the boiler (They weren't needed for the original undermounted plan) I decided the easiest way to proceed would be mounting the boiler on a frame.

Unfortunately, the size of the front roll also entailed other revisions. As in larger rear wheels. My original cute little 1/3 scale would end up being more or less a small-boilered half scale. A family friend was scrapping out some old stuff and told me I could have a set of old manure spreader wheels for less that $30 (He eventually decided $10 and some zucchini was a good trade!). Plans eventually call for grinding the rivets that hold the strakes on and having a pair of bands rolled.... But we'll probably just remove the strakes and bolt on some belting this fall.

The engine would also be mounted to the frame, rather than the boiler (something like what Frick did back in the day) It would have to be a fairly open mount to allow easy inspection of the stays, so plate was out. Channel would have to do.

I had gathered up a 3/4" Gardner governor way back in '97. It's much too large for the half mason (a 3/8" or 1/2" would be better), but it was here, and, even better, replacement parts are still available!

A new set of springs and weights only cost $45!

The steering gear would have to be fabricated. This worm set came from the Coolspring show for about $8, the shafting was a bit of stuff scrounged from the same place i got the rear wheels.

The steering wheel I found at Rough & Tumble (Sometimes it was good to have a business that sent you to the engine shows)

A fall test fire showed a problem with draft, especially when cold. It looks like a steamup fan, taller stack, and hardwoods and hard coal, lump charcoal, or find decent plans for a kerosene burner are in order.

Shortly afer that winter set in and work on this would stop for another 20 months.

I never did find gears, but I found a pair of largish #60 sprockets for $10. During one Portersville show, Ed Phillips re-bored them to fit the 2" rear axle as a demonstration in the club's 1880s machine shop.

Our place was sold, and the new landlord didn't think much of my "lawn ornament", so it had to be moved once again. A friend agreed to haul it over to the showgrounds at Portersville, which ignited another round of ambition to get it at least presentable for the club's 50th show.

I did some more work on the engine mountings, including a support for the Mason's reverse lift bar.

and a better mount for the cool looking cast iron top steering bracket.

Then another family friend donated a dog clutch that he had been 'seasoning' in his shed for about 30 years.

Which required a new crank be fabbed. it's 3/4" on one end to fit the engine and 1-1/4 on the other for the clutch and flywheel. If it looks amatuerish, well it WAS only the 3rd time that I ever ran a lathe! The jury is still out on adding a 3rd bearing for extra support to do beltwork.

A bit of cleaning up, and the spacer collars from the manure spreader worked beautifully to retain the rear wheels.

A coon's age ago I found a differential out of some sort of riding mower (Jacobsen?) It had a 32 tooth #45 sprocket, so I bored a 40 tooth #40 to fit. It'll be heavy enough to work if I don't try to pull a road grader.

A trip to the Ashtabula show at Wayne, Ohio yielded these stainless hotdog cart coolers. The look nearly perfect, but I nearly talked myself out of them 3 times because the guy was firm on having $50 for them.

Now comes another stupidity bit. I spent almost 3 weeks trying to figure out how to cut the hole in the side of the smokebox (Hole saw, cutting torch, or??) when the answer was simple and closeby all the time.... One afternoon I was sitting there looking at it when suddenly I realized/remembered that the smokebox was just BOLTED ON... as Homer says, "D'oh!"

4 bolts out and a trip up to the machine shop, and...

Of course the exhaust line just HAD to be a weird length, but luckily the club has a nice Ridgid pipe vice and threaders. (no it's not galvanized, it was painted grey a long time ago, but never used)

Unfortunately, somebody then decided it made a perfect crap catcher, so it was kind of buried DURING the show. I was busy elsewhere and didn't see all the junk until late Saturday.

When will it be finished? It's been 15 years already, what's your hurry? lol!

Way back in 1997, I decided my final project from welding school would be a miniature boiler. I spent a goodly chunk of change on materials that came with the ASME paperwork, got a set of 1993 ASME code books and did ALL the calculations - even the conflicting ones. Performed multiple destructive testing if EVERY joint set-up. AND passed my ASME welder testing. The result was a boiler the calculations said was good for 400psi (the minimum sheet thickness is .370!), but fit under EVERY part of Section I part PMB (100psi limit) Overkill? Not to the wonderful Communewealth of Pennsyltucky. They refuse to inspect it. The excuses keep changing. From, "I'm sure it's safe, but I'm not going to be the first guy to sign off on it." to "How do I know you did the calculations correctly?" to "The sheets aren't stamped with the paperwork numbers." (Btw MODEL boilers are NOT required to be stamped, as per part PMB).... Ohio OTOH doesn't bother anybody with barrels under 16". Since I can't fix bureaucratic stupid, when this is done, I'll just show it in Ohio and "T'ell wid" PA.

Anyway, the dimensions on the boiler are very close to 1/3 of my 25HP 20th Century (the barrel is 10" schedule 40, and 4 feet long the barrel of the 20th Century is 29" in diameter), but with a standard firebox (A full size Miller firebox is big enough of a maintenance headache!). I originally had a Carter steam car engine in mind and was going to make a model 20th Century. But the engine deal fell through, and never found a nearly complete Mason that I could afford.

Somewhere around '99 or Y2K I was at the Cabin Fever Expo in York, Pa as a vendor. I got a brief break and saw HALF of a Mason in the consignment area. At $800 it wasn't much of a "deal" so it was still there at the end of the show. But I decided to take a chance on it, anyway.

About 18 months later ANOTHER partial half Mason showed up on fleabay. Unfortunately, it was the same half. Fortunately, it had a complete Stephenson's reverse! I took off the reverse parts I needed off and resold the rest... for about $200 more than I paid - also thereby reducing the cost of MY engine to a less cringeworthy $600 in the process!

So now I had a boiler, and an engine. What I didn't have was a place to work, or money to spend. I was blindsided with a "trial" separation, then divorce papers soon after. Everything went into what I HOPED would be short term storage. But I was wrong. It wouldn't be until 2009 that I would again be in any position to return to it. That summer I happened to see an estate auction in the Farm and Dairy paper. It listed a BUNCH of old tractors and parts. I didn't have much money, but it sounded like a nice afternoon of free amusement anyway. In one of those seredipitous moments, I ended up coming home with this lump of "scrap" for the princely sum of $25

A roller it would be!

But it would still be another year, and yet another move, before anything much got underway. Since I hadn't done any extra calculations to mount stuff directly to the boiler (They weren't needed for the original undermounted plan) I decided the easiest way to proceed would be mounting the boiler on a frame.

Unfortunately, the size of the front roll also entailed other revisions. As in larger rear wheels. My original cute little 1/3 scale would end up being more or less a small-boilered half scale. A family friend was scrapping out some old stuff and told me I could have a set of old manure spreader wheels for less that $30 (He eventually decided $10 and some zucchini was a good trade!). Plans eventually call for grinding the rivets that hold the strakes on and having a pair of bands rolled.... But we'll probably just remove the strakes and bolt on some belting this fall.

The engine would also be mounted to the frame, rather than the boiler (something like what Frick did back in the day) It would have to be a fairly open mount to allow easy inspection of the stays, so plate was out. Channel would have to do.

I had gathered up a 3/4" Gardner governor way back in '97. It's much too large for the half mason (a 3/8" or 1/2" would be better), but it was here, and, even better, replacement parts are still available!

A new set of springs and weights only cost $45!

The steering gear would have to be fabricated. This worm set came from the Coolspring show for about $8, the shafting was a bit of stuff scrounged from the same place i got the rear wheels.

The steering wheel I found at Rough & Tumble (Sometimes it was good to have a business that sent you to the engine shows)

A fall test fire showed a problem with draft, especially when cold. It looks like a steamup fan, taller stack, and hardwoods and hard coal, lump charcoal, or find decent plans for a kerosene burner are in order.

Shortly afer that winter set in and work on this would stop for another 20 months.

I never did find gears, but I found a pair of largish #60 sprockets for $10. During one Portersville show, Ed Phillips re-bored them to fit the 2" rear axle as a demonstration in the club's 1880s machine shop.

Our place was sold, and the new landlord didn't think much of my "lawn ornament", so it had to be moved once again. A friend agreed to haul it over to the showgrounds at Portersville, which ignited another round of ambition to get it at least presentable for the club's 50th show.

I did some more work on the engine mountings, including a support for the Mason's reverse lift bar.

and a better mount for the cool looking cast iron top steering bracket.

Then another family friend donated a dog clutch that he had been 'seasoning' in his shed for about 30 years.

Which required a new crank be fabbed. it's 3/4" on one end to fit the engine and 1-1/4 on the other for the clutch and flywheel. If it looks amatuerish, well it WAS only the 3rd time that I ever ran a lathe! The jury is still out on adding a 3rd bearing for extra support to do beltwork.

A bit of cleaning up, and the spacer collars from the manure spreader worked beautifully to retain the rear wheels.

A coon's age ago I found a differential out of some sort of riding mower (Jacobsen?) It had a 32 tooth #45 sprocket, so I bored a 40 tooth #40 to fit. It'll be heavy enough to work if I don't try to pull a road grader.

A trip to the Ashtabula show at Wayne, Ohio yielded these stainless hotdog cart coolers. The look nearly perfect, but I nearly talked myself out of them 3 times because the guy was firm on having $50 for them.

Now comes another stupidity bit. I spent almost 3 weeks trying to figure out how to cut the hole in the side of the smokebox (Hole saw, cutting torch, or??) when the answer was simple and closeby all the time.... One afternoon I was sitting there looking at it when suddenly I realized/remembered that the smokebox was just BOLTED ON... as Homer says, "D'oh!"

4 bolts out and a trip up to the machine shop, and...

Of course the exhaust line just HAD to be a weird length, but luckily the club has a nice Ridgid pipe vice and threaders. (no it's not galvanized, it was painted grey a long time ago, but never used)

Unfortunately, somebody then decided it made a perfect crap catcher, so it was kind of buried DURING the show. I was busy elsewhere and didn't see all the junk until late Saturday.

When will it be finished? It's been 15 years already, what's your hurry? lol!

Last edited by a moderator: