- Joined

- Nov 7, 2014

- Messages

- 32

I just got the rotary table and have made a knob on it in delrin that worked fine, so I just dont have much experience with workholding with it yet.

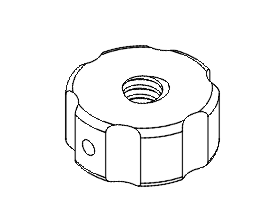

I have about 10 knobs I need to make out of 6063. I started with bandsaw cutting all of them and drill and taping the middle hole. I then mounted a section of thread in the 3 jaw chuck in the lathe and then just spun the knobs on to face and bring the OD to final size. What is left is mill work which I was planning on doing in the new rotary table. I was going to plunge the notches on the OD using a 3/8 end mill.

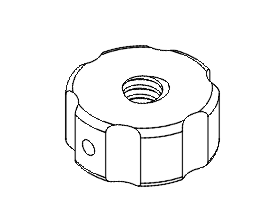

I was going to mount them the same way. Screw 3 jaw chuck to rotary table and clamp onto some thread to be able to quickly screw on the knobs to machine them. Obviously the end mill spins in the direction to unscrew the knobs so this doesnt work. I thought about making another small nut to screw down after the knob was on but then the chuck would just unscrew from the rotary table.

Im sure there is an easy way to do this but I am not coming up with anything.

Thanks for any help

I have about 10 knobs I need to make out of 6063. I started with bandsaw cutting all of them and drill and taping the middle hole. I then mounted a section of thread in the 3 jaw chuck in the lathe and then just spun the knobs on to face and bring the OD to final size. What is left is mill work which I was planning on doing in the new rotary table. I was going to plunge the notches on the OD using a 3/8 end mill.

I was going to mount them the same way. Screw 3 jaw chuck to rotary table and clamp onto some thread to be able to quickly screw on the knobs to machine them. Obviously the end mill spins in the direction to unscrew the knobs so this doesnt work. I thought about making another small nut to screw down after the knob was on but then the chuck would just unscrew from the rotary table.

Im sure there is an easy way to do this but I am not coming up with anything.

Thanks for any help