- Joined

- Jan 27, 2018

- Messages

- 43

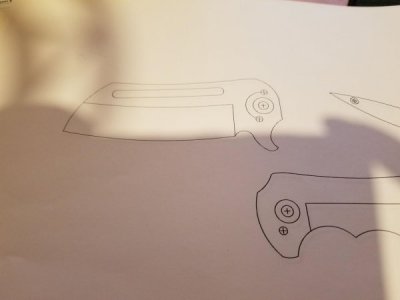

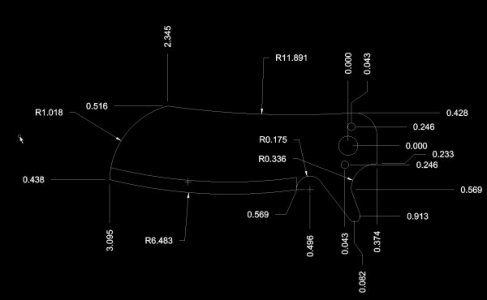

Hey guys, new to machining. Just got a Precision Mathews PM25, so far I've drilled a few holes for some of my fixed blades I do. (I make knives as a hobby) Anyways I actually bought the mill so that I could start making folding knives! I've quickly realized that my old eyeball and drill methods would not work for this. I also noticed my automatic center punch just isn't accurate enough, so I bought an optical center punch, unfortunately it seems to be defective/made poorly. The optical lens has quite a bit of wobble and causes all of my punches to be off by a few thousands. So I was wondering what people's suggestions are? I was thinking of clamping the piece of stock in the vice and lining up a center point to the cross hairs on the design and then switching to a drill. I've also heard of spot drills and center drills? What one would I need? Here is a picture to show an example of what I am working with.