Hello,

Tried cutting my own morse taper a while back and was frustrated by the slide travel being too short and the need to match up the cuts.

I have Hercus 9" an Australian clone of South Bend 9"

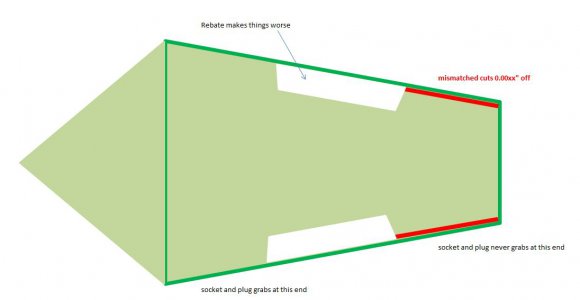

I have seen posts where people report its possible to "cheat" and hide the mismatched cuts by cutting a "relief" into the middle of the taper.

3 things puzzle me

1. Does hiding the error in this way mean that the final product is an inferior tool that will only grab over a small fraction of the taper - And this would be highlighted by testing with blue dye and a socket ? Would'nt a tiny discrepancy ie .0001" difference in the 2 tapers mean that one end would "grab" before the other and the thinner cut would be unsupported in the socket ? worst case only 50% of the socket is grabbing ?

2. Any good tricks for "matching up the cuts" that us newbies would like to know about ?

................ and yes I know about taper jigs and offset jigs for the tailpost ........ am really keen to find out if there are any tricks to "matching the cuts"

3 I currently get my best finishes with a shearing tool. Would a shearing tool give a good enough finish to a home made morse taper or would some people use a toolpost grinder ? Again the same problem would exist with the limited travel and the resulting dogleg.

Regards

Bill

Tried cutting my own morse taper a while back and was frustrated by the slide travel being too short and the need to match up the cuts.

I have Hercus 9" an Australian clone of South Bend 9"

I have seen posts where people report its possible to "cheat" and hide the mismatched cuts by cutting a "relief" into the middle of the taper.

3 things puzzle me

1. Does hiding the error in this way mean that the final product is an inferior tool that will only grab over a small fraction of the taper - And this would be highlighted by testing with blue dye and a socket ? Would'nt a tiny discrepancy ie .0001" difference in the 2 tapers mean that one end would "grab" before the other and the thinner cut would be unsupported in the socket ? worst case only 50% of the socket is grabbing ?

2. Any good tricks for "matching up the cuts" that us newbies would like to know about ?

................ and yes I know about taper jigs and offset jigs for the tailpost ........ am really keen to find out if there are any tricks to "matching the cuts"

3 I currently get my best finishes with a shearing tool. Would a shearing tool give a good enough finish to a home made morse taper or would some people use a toolpost grinder ? Again the same problem would exist with the limited travel and the resulting dogleg.

Regards

Bill