- Joined

- Feb 2, 2013

- Messages

- 3,954

I needed a rack for my R8 toolholders and collets.

so i looked around the shop to see what i had to make a collet rack from.

sure, i could have just bought a commercially made rack- but what is the fun in that???

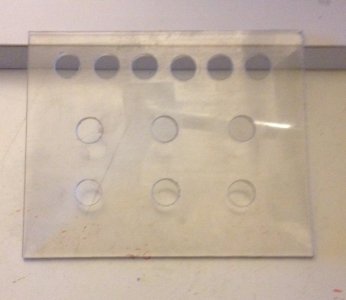

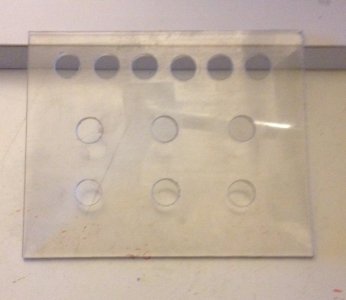

i started off with a hunk of reclaimed 1/4" polycarbonate that i just couldn't bear to throw away.

using my tablesaw, i rendered a piece 11" X 9".

i laid out the spots to drill and using the drill press and clamps i went to work at punching the 12- 7/8" holes

then deburred

then i checked fit and spacing

the top row was intended for collets

the 2nd and 3rd rows were spaced out for R8 Weldon toolholders, R8 mounted Drill Chuck, and R8 mounted Fly Cutter

stay tuned for act II !

so i looked around the shop to see what i had to make a collet rack from.

sure, i could have just bought a commercially made rack- but what is the fun in that???

i started off with a hunk of reclaimed 1/4" polycarbonate that i just couldn't bear to throw away.

using my tablesaw, i rendered a piece 11" X 9".

i laid out the spots to drill and using the drill press and clamps i went to work at punching the 12- 7/8" holes

then deburred

then i checked fit and spacing

the top row was intended for collets

the 2nd and 3rd rows were spaced out for R8 Weldon toolholders, R8 mounted Drill Chuck, and R8 mounted Fly Cutter

stay tuned for act II !

Last edited: