- Joined

- Jan 27, 2017

- Messages

- 16

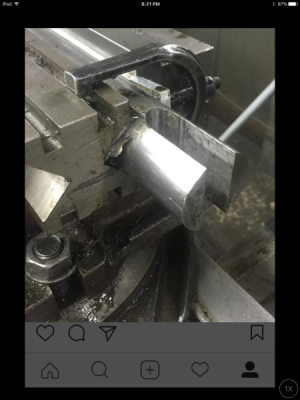

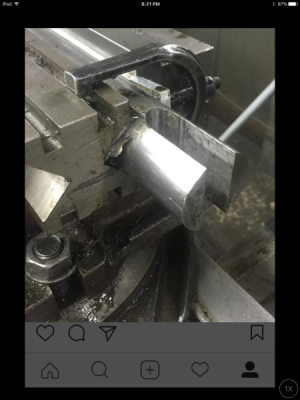

last friday I cut this slot using a 1/2" 4 flute carbide cutter running at 1200rpm. I cut at .030 increaments of the knee crank. I flooded the cutter with molydee oil. I realized I was running slow. The final width of slot needs to be .635" in 1.5" dia shaft

Today I proceeded to side mill the slot at full depth with .010" of side cut at 2000rpm and got a very nice surface finish but it was taking to long. I believe it was singing when I tried to take a larger, .o20 side cut at full depth.

So I stepped up to a 4 flute 5/8 hss endmill and milled using the bottom of endmill at .030" depth increments at 800rpm. I Used liberal amount of oil

I plan to switch back to that 1/2 endmill and finish the slot to size. I plan on endmiling the fillets/radii of the slot by plungle cutting followed by conventionally side milling the slot at full 1.5" depth. I relize that I should have used a slotting endmill from the job.

Does anyone have any comments or suggestions?

Today I proceeded to side mill the slot at full depth with .010" of side cut at 2000rpm and got a very nice surface finish but it was taking to long. I believe it was singing when I tried to take a larger, .o20 side cut at full depth.

So I stepped up to a 4 flute 5/8 hss endmill and milled using the bottom of endmill at .030" depth increments at 800rpm. I Used liberal amount of oil

I plan to switch back to that 1/2 endmill and finish the slot to size. I plan on endmiling the fillets/radii of the slot by plungle cutting followed by conventionally side milling the slot at full 1.5" depth. I relize that I should have used a slotting endmill from the job.

Does anyone have any comments or suggestions?

Last edited: