- Joined

- Dec 12, 2020

- Messages

- 33

Hey guys,

I recently got a PM1340GT and it is sitting on leveling feet which got me thinking about my mill.

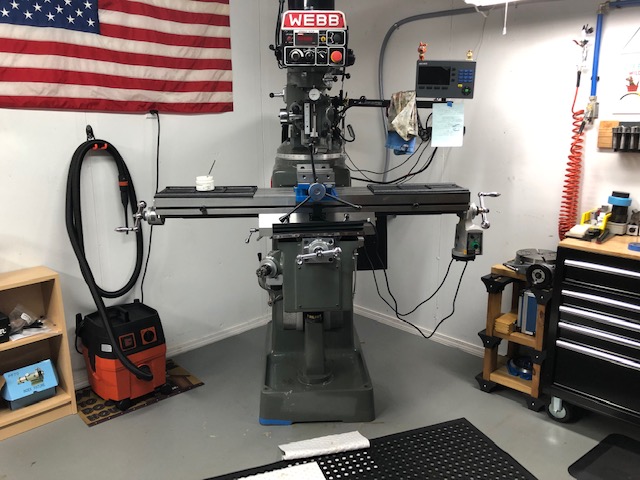

I have a Webb Champ 3EVS 10x50. It weighs about 3,300lbs and I have it sitting catty corner in my shop. Here are some pics:

I have a shade over 6" of clearance above the motor.

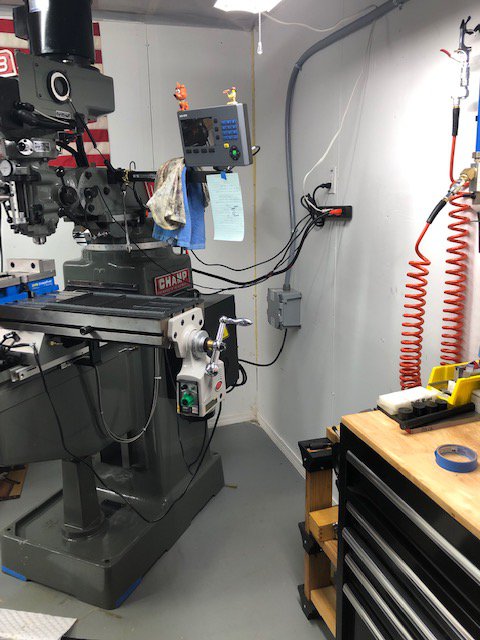

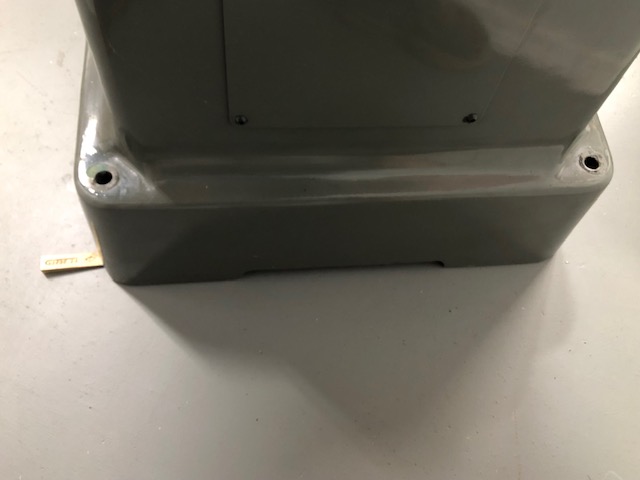

When I first got the mill it was rocking on the floor. The back right and front left corners were seesawing so to speak. I put a steel wedge under the back right corner and tapped it in a little bit so that it doesn't move. I want to find a better solution than this wedge. I'd like it to sit more solidly. I have outlined in the below pictures where it is actually touching the floor by placing blue tape (where it touches).

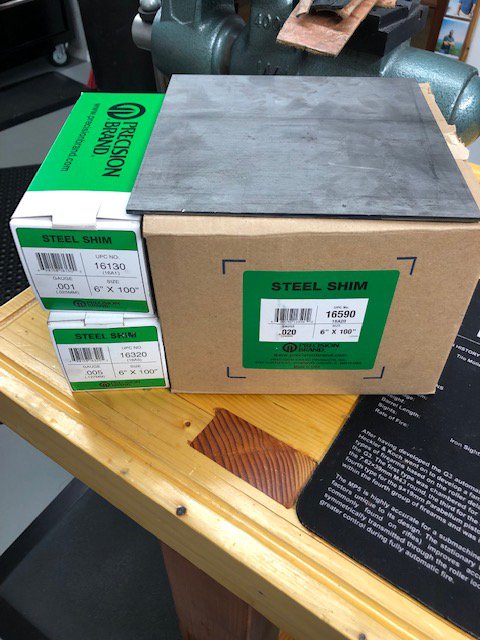

I have shims, .001", .005", .020" and a larger sheet of .115" that I can use:

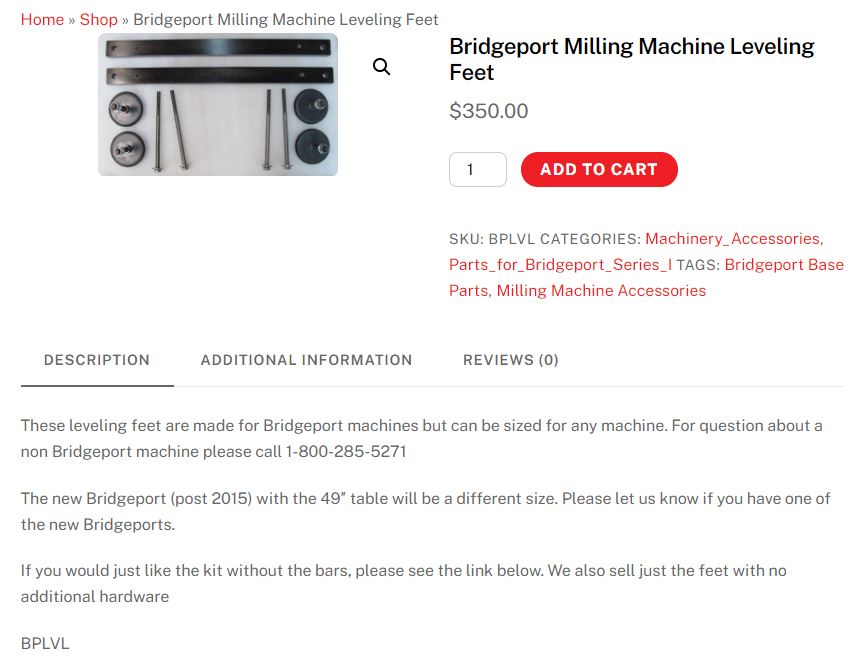

Here are my questions. I'd love to put the mill on leveling feet with a steel bar going across the front and back that the mill would sit on. Like the ones sold by H&W machine repair:

I contacted them and they would make a custom set that matches the hole spacing on my mill. At that point it would sit very solidly on the floor and I could even level it like I did my lathe. Not that it needs to be perfectly level but it can't hurt.

The problem with this option is that I would have to stand on my toes to change endmills. I can stand flat footed right now and swap endmills but raising it up another 3" would really have me reaching. I don' know if having the motor head that much closer to the ceiling would be an issue either. I don't want to put a maxi torque on there either.

So it seems I'm left with stuffing shims under the mill. Anyone have any suggestions?

Thanks,

Zack

I recently got a PM1340GT and it is sitting on leveling feet which got me thinking about my mill.

I have a Webb Champ 3EVS 10x50. It weighs about 3,300lbs and I have it sitting catty corner in my shop. Here are some pics:

I have a shade over 6" of clearance above the motor.

When I first got the mill it was rocking on the floor. The back right and front left corners were seesawing so to speak. I put a steel wedge under the back right corner and tapped it in a little bit so that it doesn't move. I want to find a better solution than this wedge. I'd like it to sit more solidly. I have outlined in the below pictures where it is actually touching the floor by placing blue tape (where it touches).

I have shims, .001", .005", .020" and a larger sheet of .115" that I can use:

Here are my questions. I'd love to put the mill on leveling feet with a steel bar going across the front and back that the mill would sit on. Like the ones sold by H&W machine repair:

I contacted them and they would make a custom set that matches the hole spacing on my mill. At that point it would sit very solidly on the floor and I could even level it like I did my lathe. Not that it needs to be perfectly level but it can't hurt.

The problem with this option is that I would have to stand on my toes to change endmills. I can stand flat footed right now and swap endmills but raising it up another 3" would really have me reaching. I don' know if having the motor head that much closer to the ceiling would be an issue either. I don't want to put a maxi torque on there either.

So it seems I'm left with stuffing shims under the mill. Anyone have any suggestions?

Thanks,

Zack