- Joined

- Jan 2, 2014

- Messages

- 9,042

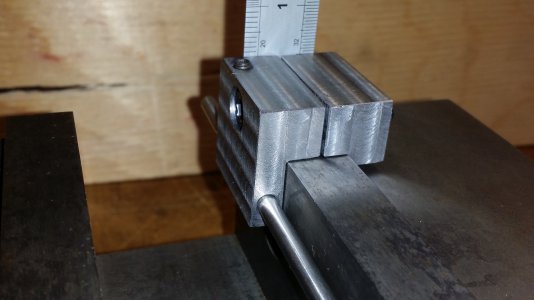

A few years back I picked up this 6" milling vise.

(.........and NO the battle scars were not caused by me, I got it used!)

I have wanted to build a jaw clamp and stop system that would allow removing the work-piece and putting it back in the same place.

Each jaw is just over 1/8" above the vise body.

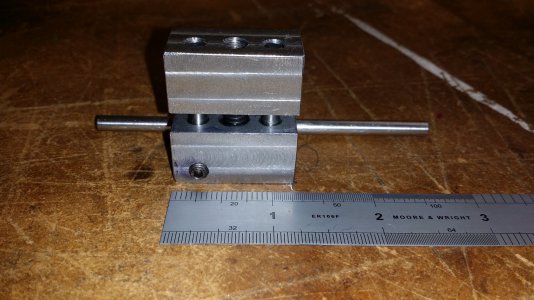

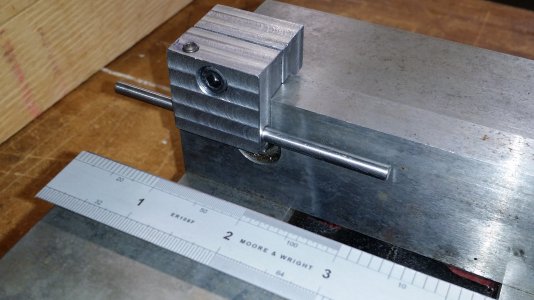

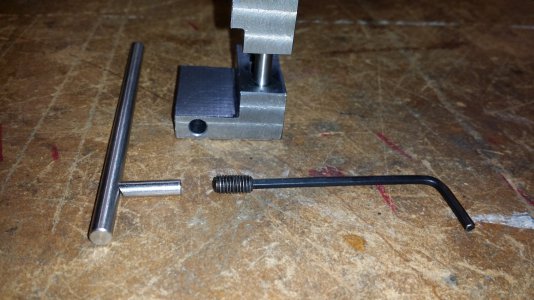

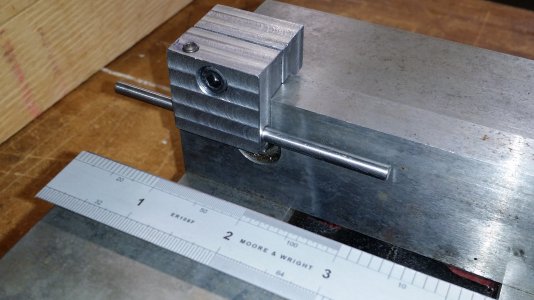

I looked at a few different designs and builds and then came up with this.

It is made from 1" x 2" hot rolled steel.

I used 3/16" dowel pins for the sliders, a 1/4"-20 Socket-Head Cap Screw (SHCS) for the clamp bolt, a 3/16" shaft for the adjustable stop and a #10-32 set-screw for the brake. The brake also uses a small rod with a notch as the "brake shoe". It was something a I wanted to try and it works very well! With the set-screw just finger tight the stop rod is solid.

I'll be back in a few minutes with more photos...........stay tuned!

-brino

(.........and NO the battle scars were not caused by me, I got it used!)

I have wanted to build a jaw clamp and stop system that would allow removing the work-piece and putting it back in the same place.

Each jaw is just over 1/8" above the vise body.

I looked at a few different designs and builds and then came up with this.

It is made from 1" x 2" hot rolled steel.

I used 3/16" dowel pins for the sliders, a 1/4"-20 Socket-Head Cap Screw (SHCS) for the clamp bolt, a 3/16" shaft for the adjustable stop and a #10-32 set-screw for the brake. The brake also uses a small rod with a notch as the "brake shoe". It was something a I wanted to try and it works very well! With the set-screw just finger tight the stop rod is solid.

I'll be back in a few minutes with more photos...........stay tuned!

-brino