- Joined

- Mar 14, 2017

- Messages

- 7

Hi,

I'm creating a RBS using wood, brass and glass marbles as the media. I'm pretty good at woodworking, but very new to machining.

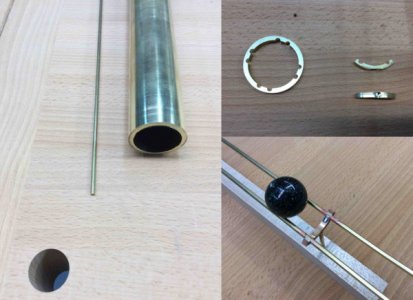

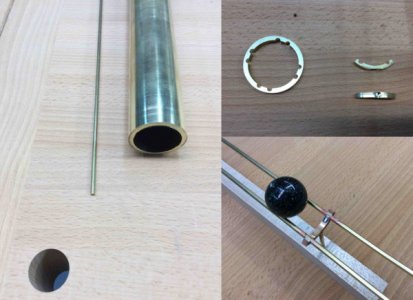

My router table makes for a poor mill with the use of jigs and, as you can image, it's not very accurate or easy. The photo shows what I'm attempting. On the left is the raw stock, a brass pipe 1 5/8" diameter with 1/4" walls (also shown is a 1/8" rod used as track). I use a jig with a dremel to cut off a 1/4" circle. A jig on the router table mills the 1/8" holes in the ring (next photo clockwise). The ring is cut into 4ths, a small flat made on the each of these track supports and a hole drilled into, but not thru, the flat. Add some solder and you get to the picture on the bottom right.: a marble rolling of a track in dire need of a clean up!

Here are my assumptions based on reading a bunch of books:

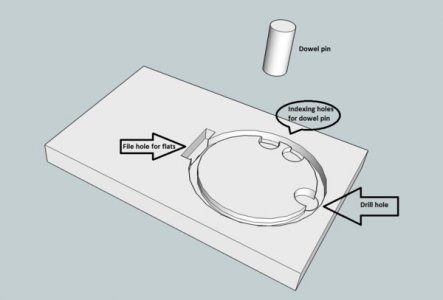

- A mill with a rotary table (?) drills the 1/8" holes.

- An end mill cuts the flat on each track support

- A drill cuts the hole in the flat

Are these good assumptions?

Also, can a mill be used to cut the 1/4" rings from the pipe? (Don't want to buy a lathe... yet!)

Assuming the dremel has butchered out a ring. Can the mill surface this piece of uneven thickness?

How to hold (with accuracy) the track supports? Should I drill the holes (and make the flats) before cutting the ring in 4ths?

So... anyone want to convince me to buy a mill!?

thanks,

mark

I'm creating a RBS using wood, brass and glass marbles as the media. I'm pretty good at woodworking, but very new to machining.

My router table makes for a poor mill with the use of jigs and, as you can image, it's not very accurate or easy. The photo shows what I'm attempting. On the left is the raw stock, a brass pipe 1 5/8" diameter with 1/4" walls (also shown is a 1/8" rod used as track). I use a jig with a dremel to cut off a 1/4" circle. A jig on the router table mills the 1/8" holes in the ring (next photo clockwise). The ring is cut into 4ths, a small flat made on the each of these track supports and a hole drilled into, but not thru, the flat. Add some solder and you get to the picture on the bottom right.: a marble rolling of a track in dire need of a clean up!

Here are my assumptions based on reading a bunch of books:

- A mill with a rotary table (?) drills the 1/8" holes.

- An end mill cuts the flat on each track support

- A drill cuts the hole in the flat

Are these good assumptions?

Also, can a mill be used to cut the 1/4" rings from the pipe? (Don't want to buy a lathe... yet!)

Assuming the dremel has butchered out a ring. Can the mill surface this piece of uneven thickness?

How to hold (with accuracy) the track supports? Should I drill the holes (and make the flats) before cutting the ring in 4ths?

So... anyone want to convince me to buy a mill!?

thanks,

mark