- Joined

- Jun 12, 2014

- Messages

- 5,055

These three QMT models share the same micrometer stop, unfortunately like so many items these days the micrometer stops are on back order. I have made several of these micrometer stops in various different iterations for different individuals so they could use one of my proximity stop systems and didn't have to wait several months to wait for stock to replenish. The stock micrometer uses a barrel that extends beyond the stop, so make it a bit difficult to use if you need to work close to the headstoock, and also the micrometer shaft rotates as you advance the shaft. I just finished a more recent micrometer stop for a 1340GT owner, that uses a center thumb wheel which advances a partially threaded shaft, the shaft is slotted and uses a fixing Allen screw to prevent rotation. I make the body out of aluminum, it is easy to work with, but it could also be made out of some type of cast iron block. Most of the parts are not to difficult to fabricate, but one needs to figure out the sequencing of the steps. In this case the shaft and thumb wheel were made out of O1 rod, the base is some 1/2" steel bar that I had in my stock. Pictures and and some dimensions are posted, I made a few mods to the layout, I would verify dimensions to your lathe. This will not fit larger 1340/1440 lathes such as the ERL/TRL/RML types.

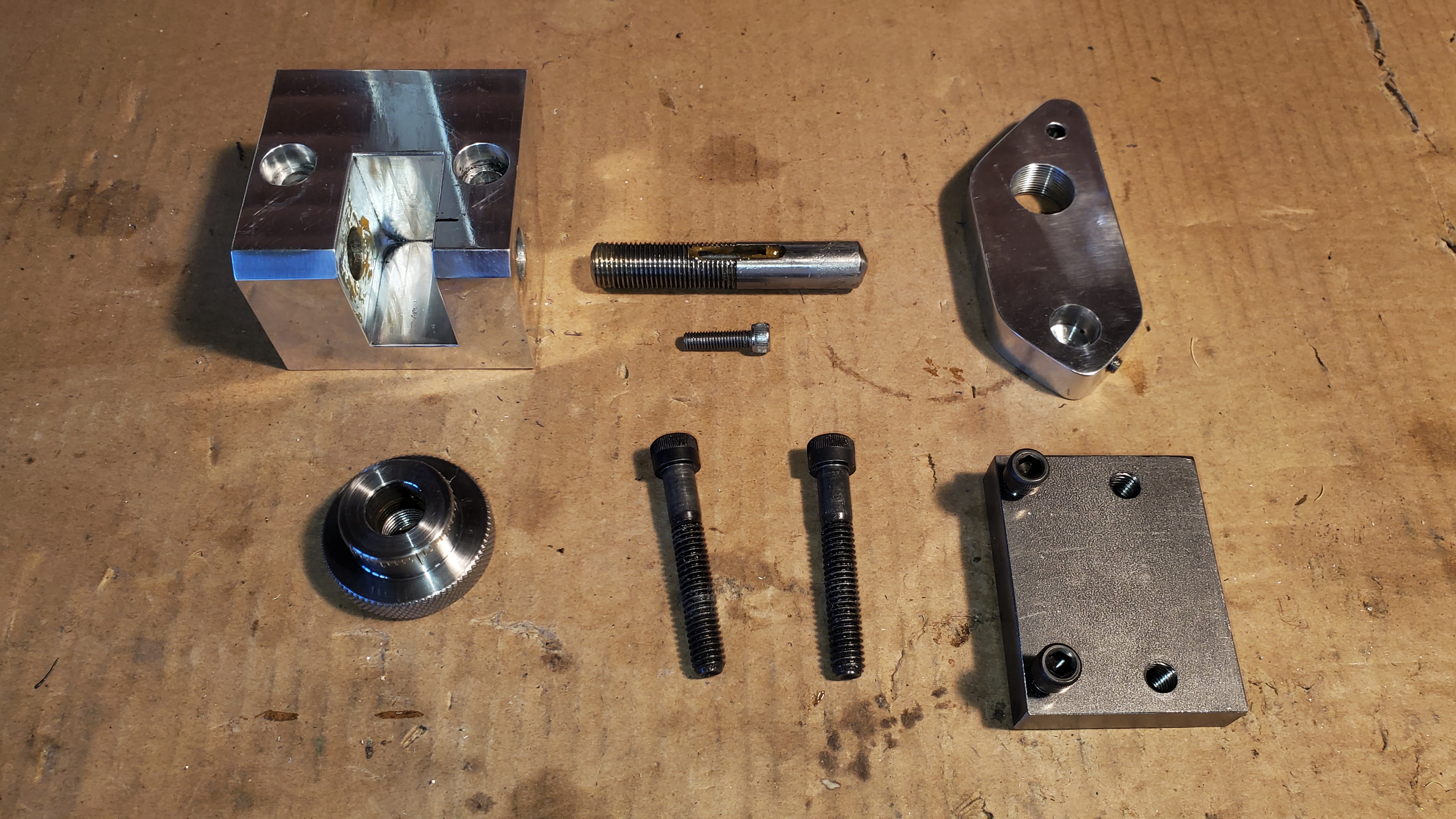

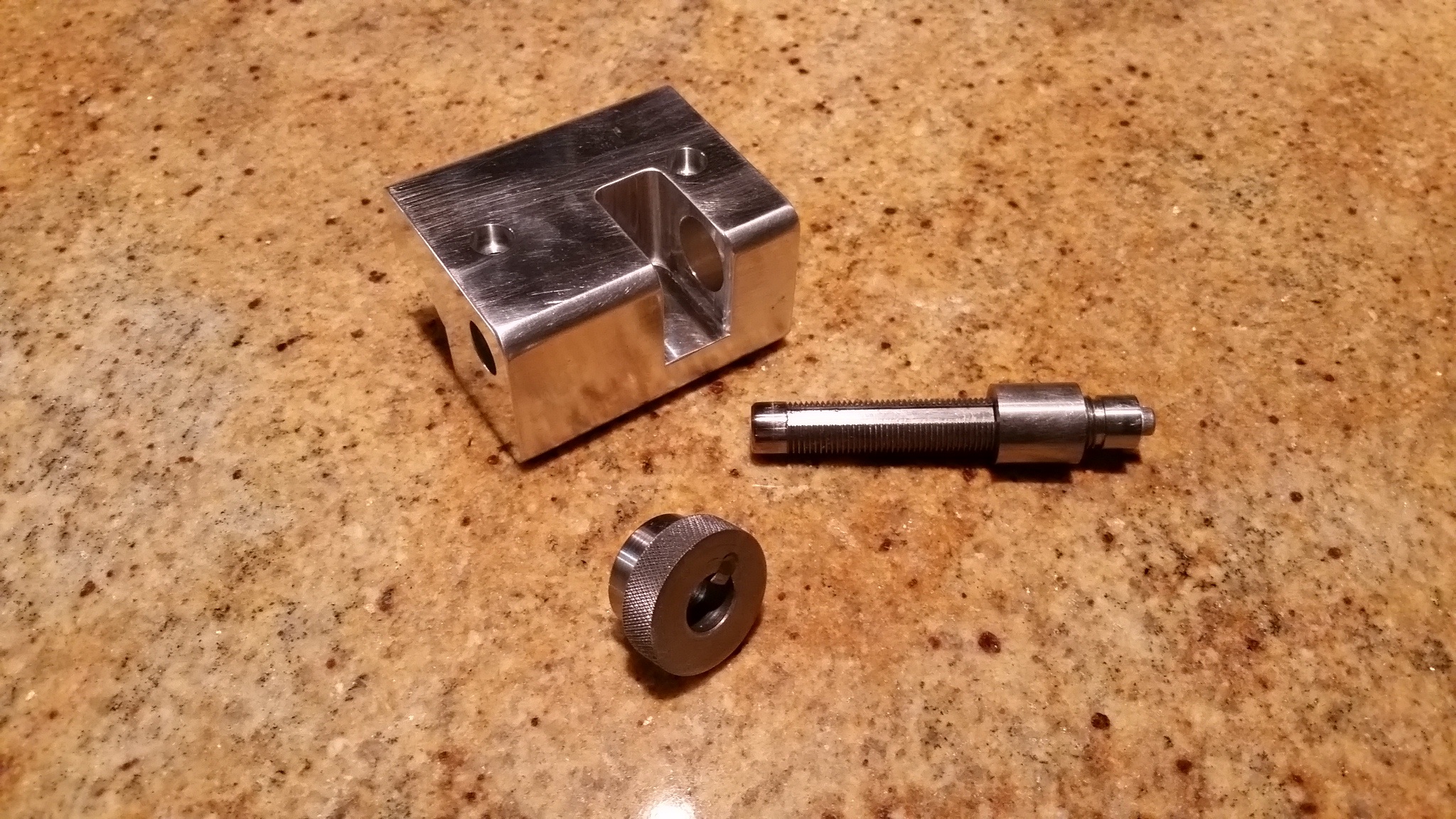

Basic parts, body, thumb wheel, shaft, base plate, hardware and I have a proximity sensor mounting plate for this version otherwise the shaft would have a flat end.

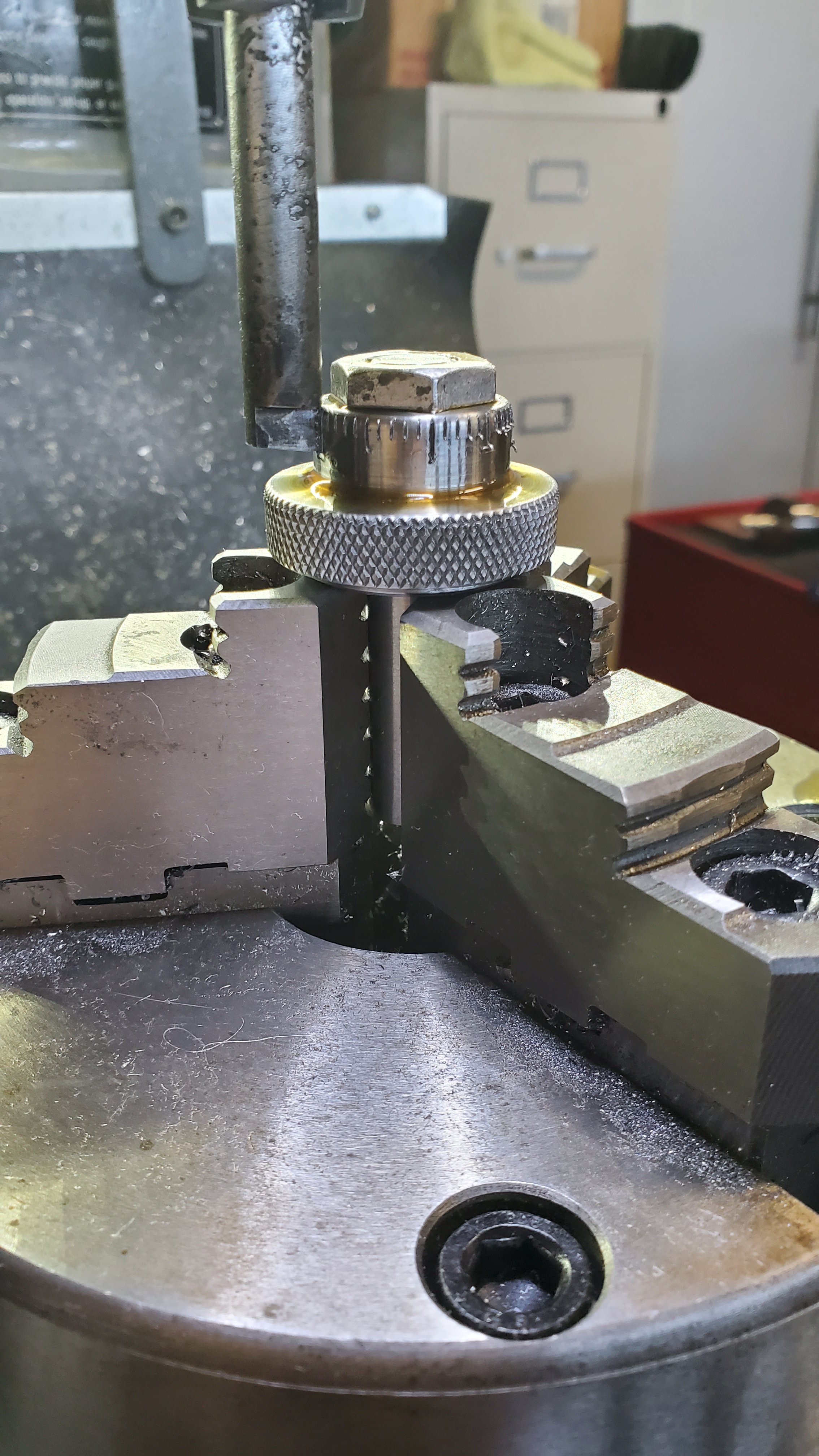

I used a rotary table to scribe the increment marks, major 0.01" increments are 0.25"x0.15" deep, minor 0.05" increments 0.15"x0.1", ticks 0.001' increments 0.1"x0.1".

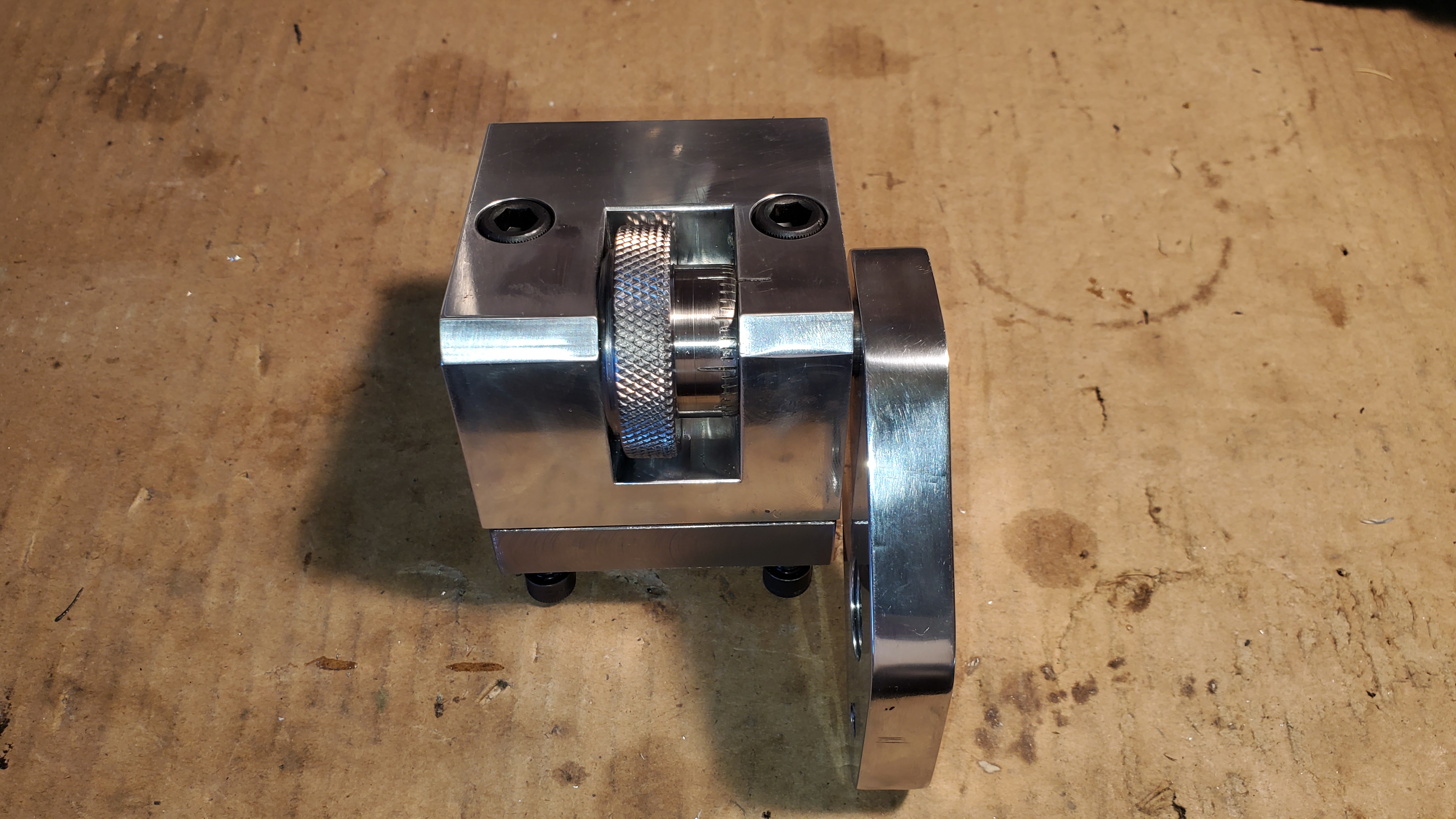

Assembled micrometer stop, total travel is ~1", the slot for the thumb wheel is milled after making the thumb wheel, the fit is withing a few 1/10,00". The thumb wheel was hand tapped with a tailstock guide before parting off, the micrometer shaft was threaded on the lathe for a close tolerance fit to the thumb wheel.

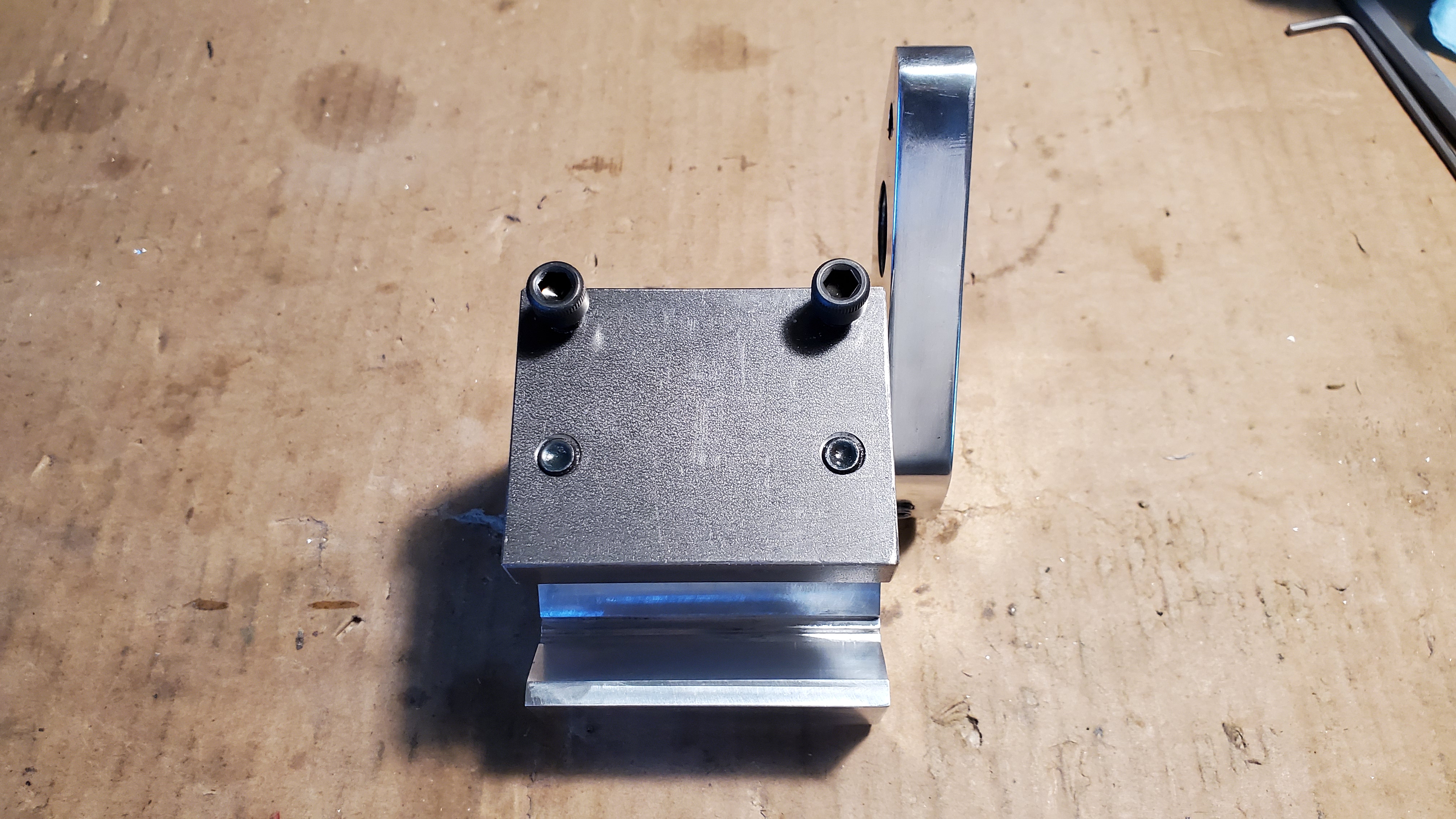

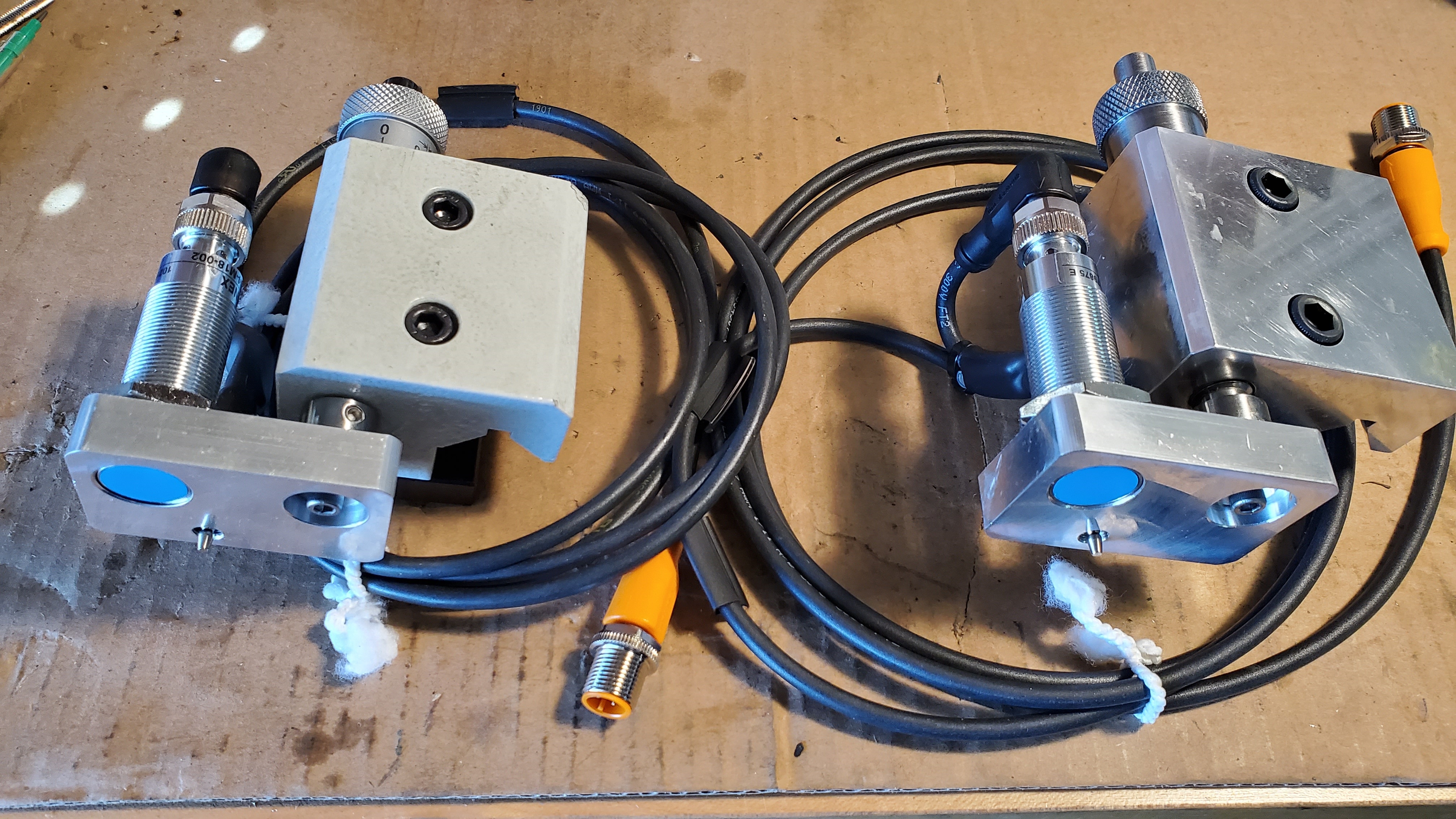

Previous version I made several months ago which was modeled off of the original.

Previous micrometer I built for my 1340GT with a steel shaft and threaded steel insert.

Basic parts, body, thumb wheel, shaft, base plate, hardware and I have a proximity sensor mounting plate for this version otherwise the shaft would have a flat end.

I used a rotary table to scribe the increment marks, major 0.01" increments are 0.25"x0.15" deep, minor 0.05" increments 0.15"x0.1", ticks 0.001' increments 0.1"x0.1".

Assembled micrometer stop, total travel is ~1", the slot for the thumb wheel is milled after making the thumb wheel, the fit is withing a few 1/10,00". The thumb wheel was hand tapped with a tailstock guide before parting off, the micrometer shaft was threaded on the lathe for a close tolerance fit to the thumb wheel.

Previous version I made several months ago which was modeled off of the original.

Previous micrometer I built for my 1340GT with a steel shaft and threaded steel insert.