- Joined

- Apr 28, 2013

- Messages

- 84

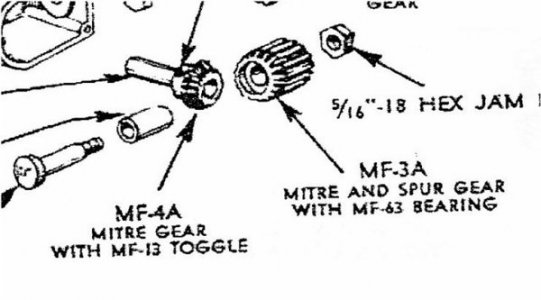

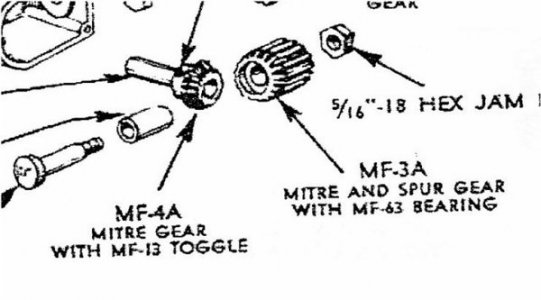

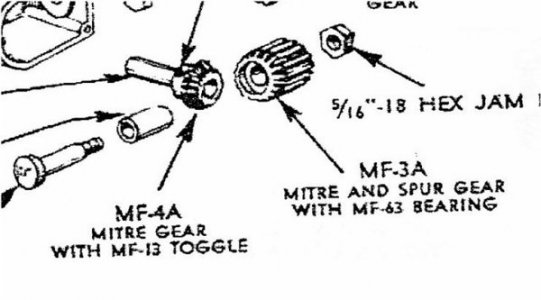

I finally got my MFC running this weekend and I discovered that the bevel gears in the auto feed are badly worn. There's only one set on eBay right now and they're $180 - ouch.

Since I have a lathe and a shaper, I was thinking that it would be reasonably simple to have someone fill them with brazing so I could re-machine the teeth. In my mind, the biggest challenge is holding and indexing the parts. My first thought is to hold the cutter in a toolholder so it's perpindicular to the table. Then if I mount my spindex 45 degrees from the axis of the ram, I should be able to cut the bevel teeth.

3A and 4A are the ones that are worn out.

Any other ideas?

Since I have a lathe and a shaper, I was thinking that it would be reasonably simple to have someone fill them with brazing so I could re-machine the teeth. In my mind, the biggest challenge is holding and indexing the parts. My first thought is to hold the cutter in a toolholder so it's perpindicular to the table. Then if I mount my spindex 45 degrees from the axis of the ram, I should be able to cut the bevel teeth.

3A and 4A are the ones that are worn out.

Any other ideas?