- Joined

- Mar 22, 2014

- Messages

- 870

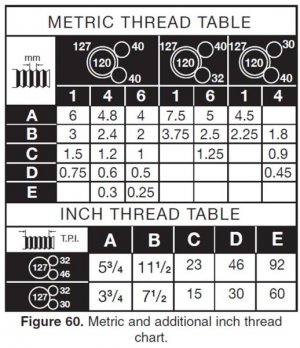

I just realized that the Atlas/Craftsman Quick Change gear box does not provide a means of cutting metric threads. According to Tubal Cain, I would need to convert the lathe to a manual change gear configuration in order to do metric. This would be too costly for me.

Anyone know of another method? I can imagine changing the ratio between the spindle and the Quick Change gearbox by just changing two gears.

Anyone know of another method? I can imagine changing the ratio between the spindle and the Quick Change gearbox by just changing two gears.