- Joined

- Feb 2, 2013

- Messages

- 3,913

I reclaimed some aluminum from a casting from a Hobart Meat Saw.

the part is considered consumable by the manufacturer, so i get about 6 or 7 of these castings a year on average

i have used the aluminum for all kinds of beating devices and press plates and spacers.

this time a clamping pallet.

here is the tale...

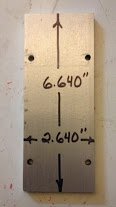

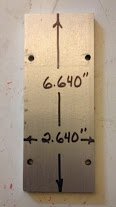

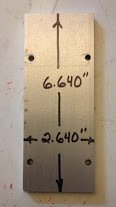

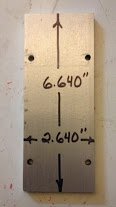

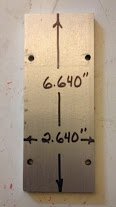

after planing the surface to a thickness i could easily work with, i parted a clear piece 6.640" long

i drilled 21- #7 holes @ 1" centers and managed to miss the OEM holes

& tapped them to 1/4"-20tpi

i snuck in an extra row of holes at the bottom

the clamping pallet will be useful when an item is oddly shaped or otherwise wouldn't clamp well in a vise

thanks for looking!

the part is considered consumable by the manufacturer, so i get about 6 or 7 of these castings a year on average

i have used the aluminum for all kinds of beating devices and press plates and spacers.

this time a clamping pallet.

here is the tale...

after planing the surface to a thickness i could easily work with, i parted a clear piece 6.640" long

i drilled 21- #7 holes @ 1" centers and managed to miss the OEM holes

& tapped them to 1/4"-20tpi

i snuck in an extra row of holes at the bottom

the clamping pallet will be useful when an item is oddly shaped or otherwise wouldn't clamp well in a vise

thanks for looking!

Last edited: