I really didn't need another lathe, but I saw an Emco Maximat for sale with a stand, a 3 jaw chuck, a small vise, faceplate and various other parts for a very good price, so I couldn't pass it up. A very nice fellow up in Newark, Delaware even helped load it on my trailer.

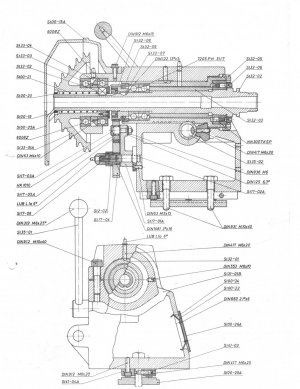

I have not yet checked out the motors, but I noticed the mill/drill head appears to have dry grease in it. Has anyone pulled one of these apart? The drive pulley end has some sort of spring pin, and it looks like the rest of it comes apart from the chuck end, as there's two rings with pin holes for disassembly. Any trick to getting out the spring pin out of the pulley end?

The manual indicates use of Esso Nebula EP No. 1 grease. Can anyone provide advice as to a source for this grease or a suitable substitute?

The bed has a serial number of 651014. Any idea of how old this machine might be? I have not found anything other than "Maximat Standard" on the machine itself, but some literature that came with the manual indicates it may be a model MQ-3100.

Here's some pics and info.

I appreciate any guidance/advice that might be offered.

TomKro

I have not yet checked out the motors, but I noticed the mill/drill head appears to have dry grease in it. Has anyone pulled one of these apart? The drive pulley end has some sort of spring pin, and it looks like the rest of it comes apart from the chuck end, as there's two rings with pin holes for disassembly. Any trick to getting out the spring pin out of the pulley end?

The manual indicates use of Esso Nebula EP No. 1 grease. Can anyone provide advice as to a source for this grease or a suitable substitute?

The bed has a serial number of 651014. Any idea of how old this machine might be? I have not found anything other than "Maximat Standard" on the machine itself, but some literature that came with the manual indicates it may be a model MQ-3100.

Here's some pics and info.

I appreciate any guidance/advice that might be offered.

TomKro