Please see that attached sheet which "lathe tool holders and inserts recommendations which gives some further info and suggested holders and inserts. Also some other information.

So CCMT type of inserts are probably the most commonly used general insert for smaller lathes (5 Hp and under). So the insert holders have a specific nomenclature as above. The tool holder is specific for a certain size insert, typically holders with the same size shank will use the same size inserts. So in this case 5/8" and 3/4" holder will typically use a 33.2X size insert the is a 3/8" size insert with a insert pocket neutral rake. The CCMT09T304 is just a different nomenclature ISO (vs. ANSI) for the same thing. Insert holders may have a positive, neutral or negative rake for the insert pocket. A positive rake is usually for smaller machines and with less Hp, typically 2 Hp and less, Neutral for 2-5Hp lathes and negative for 5 Hp and greater (more rigid lathes). But insert edge profiles also have different edge profiles (rakes), so you can have a neutral or negative holder pocket but the insert edge can be positive. Think of it as the more positive the edge profile the more fragile the edge and the finer the cut, less postive is more durable and can take heavier interrupted cuts.

So for the most part you would be using a 33.51 size insert, the last number is the nose radius size. A 33.52 (larger radius) would give a smoother cut, but requires a deeper cut. A CCMT insert "M" is molded so not as sharp but works well in harder materials, a CCGT the "G" is a ground sharper edge which is more fragile but works better in softer materials (like aluminum and plastics). Then there are edge profiles, chip breakers and coatings which can be numerous. Usually the back of the insert box gives you recommendations. I will say, that the cheap inserts do not cut as well nor last as well, but you can buy brand name inserts on eBay at a fraction of retail. YOU do need to be careful as there are a lot of counterfeit ones so look carefully at the box and verify with the seller. I typically use Iscar, Kennametal, Creazitizit, Korloy and Sandvik. Once I find something that works well like the Iscar below, I stick with that insert. I only switch if I am doing something like hardened steels.

Iscar insert is very good for a wide range of materials, will even work with aluminum, but recommend a CCGT if you do a lot of aluminum

ISCAR CCMT 3-1-SM / CCMT09T304-SM CCMT 32.51

https://www.ebay.com/itm/10-new-ISC...ade-IC907-Carbide-Inserts-Israel/233031871387

https://www.ebay.com/itm/SALE-CCMT-3-1-SM-IC907-ISCAR-10-INSERTS-FACTORY-PACK/401652528960

On softer metals and fine cutting of steel CCGT 32.51 Creazitizit or Korloy (I have bought from these sources both these sellers they seem legit)

https://www.ebay.com/itm/10pcs-CCGT-32-51FN-25P-H210T-CERATIZIT-ccgt-09t304fn-25p-h210t/291946846515

https://www.ebay.com/itm/New-KORLOY...-CNC-Carbide-Insert-10PCS-in-BOX/122617092912

Might look into WNMG for Aluminum if you have a larger lathe 2 Hp 12" swing or larger, Seco are hard to find so there are Iscar models in 5/8" and 3/4" holders that work well. I use Creazitizit or Korloy inserts 331.

On some inserts like the neutral type used for chamfering I run one insert so for the SCMCN the CCMT Iscar would be for all materials. CCGT can be used for lighter cuts and finish cuts in steel, but the edges are more fragile.

On boring bar you often want a bit more radius at the tip, so something like a 32.52 CCMT insert. Keep the boring bar stick out as short as possible.

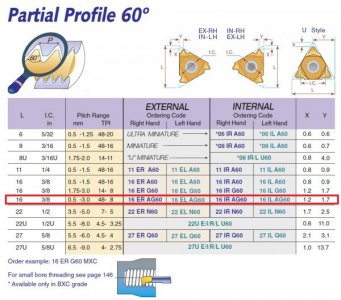

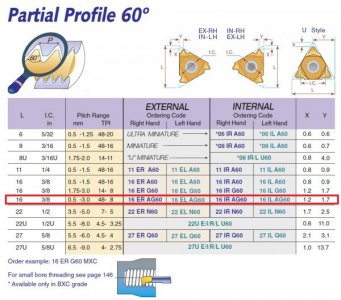

On threading, I use lay down insert holders, I find they work better than the vertical type, at least for my setup.

So for general machining you will predominately be using the same inserts/sizes. Then you can get into other types of tool holders and inserts as needed for your type of work, but normally I only have two types of inserts for each type of insert, one molded and coated and the other is ground uncoated and polished carbide.

Mark.