- Joined

- May 7, 2020

- Messages

- 267

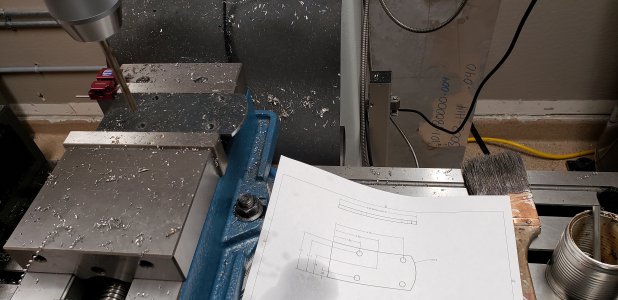

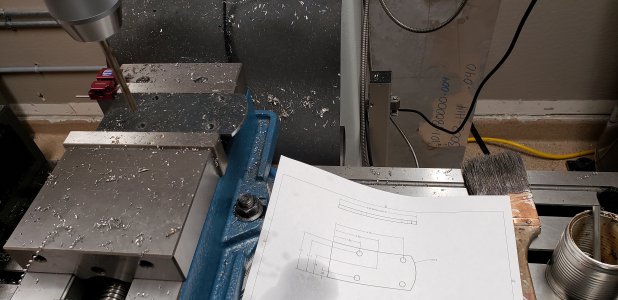

One of our product lines (our side-hustle low volume product lines) needed a radius operation for serial production.

2.5" x 3/16 bar stock. We cut to 6" length. The workholding on the rotary can be tricky. So I made a fixture that would securely hold the piece laterally.

Milled a slot in some aluminum stock. Bit of a hack job...but made clearance for the corners (no broaching allowed). And I get that we didn't need all that width either...fixtures just need to work. Good and ugly but effective.

Made keys for the t-slots. So no need to really go nuts on work holding. A really nice fit on those. No wiggle at all.

So now we have a holding fixture...just enough clearance for batch variances in the bar stock.

Needed to trim down some t-nuts to fit the 10" Vertex rotary table. Should have known these were hardened. Ruined my Hertel cobalt rougher. Boo. Carbide for the win.

Now we can just crank these out. Works great and easy and fast to lock in a new part with minimal clamping needed.

Radius complete. Move on to drilling operation.

The weld cart "feet" are now ready for casters.

Fun little project that will save us a lot of time.

2.5" x 3/16 bar stock. We cut to 6" length. The workholding on the rotary can be tricky. So I made a fixture that would securely hold the piece laterally.

Milled a slot in some aluminum stock. Bit of a hack job...but made clearance for the corners (no broaching allowed). And I get that we didn't need all that width either...fixtures just need to work. Good and ugly but effective.

Made keys for the t-slots. So no need to really go nuts on work holding. A really nice fit on those. No wiggle at all.

So now we have a holding fixture...just enough clearance for batch variances in the bar stock.

Needed to trim down some t-nuts to fit the 10" Vertex rotary table. Should have known these were hardened. Ruined my Hertel cobalt rougher. Boo. Carbide for the win.

Now we can just crank these out. Works great and easy and fast to lock in a new part with minimal clamping needed.

Radius complete. Move on to drilling operation.

The weld cart "feet" are now ready for casters.

Fun little project that will save us a lot of time.

Last edited: