Yes: Be sure to leave some space between the top of the right angle attachment and the bottom of the headstock casting. The attachment will move upwards as you tighten the draw bar. I have an extended drawbar(has a longer hex on the top) that I use with the attachment. Before that,I was able to reach the drawbar with a long 3/4" socket.

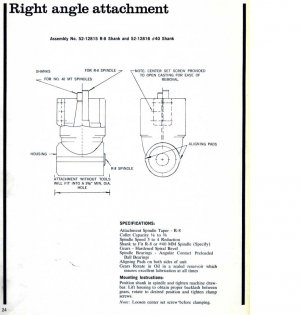

Don't forget to tighten the 2 Allen head screws after you get the drawbar tightened,BUT FIRST,back off the screw that is there to slightly expand the attachment's hole,so you can get it onto your quill. If you forget to back off the expansion screw,you can easily crack the thin casting of the attachment,and ruin it.

It has been a long time since I used the attachment since I have a horizontal mill now. So,this is written a little backwards as I remembered what all to do. But BE CAREFUL to follow every direction here,or you can break the attachment. I only use mine when I have to machine a piece that is too long for the travel of the horizontal mill.

One last thing: I thoroughly recommend removing the little stud that projects into the inside of the spindle. It slides into the groove in the R8 collets. But,it is not really needed,and can cause BAD trouble: I had a used rt. angle attachment,and the drive screw had buggered its way sideways into the groove. I had a bad time getting the attachment OFF the mill after it was used. The rather intermittent load on the attachment's spindle WILL enable even a real Bridgeport attachment to get this sideways wear in its R8. I have had no trouble with any collet slipping around since removing that blasted drive stud. It has a set screw on top of it,so remove BOTH these screws. You have to unscrew the ring at the bottom of the spindle,and I THINK it has a left hand thread(been a while). Under the ring,you can get at the screw and the stud under it. I used a wooden clamp to unscrew mine,so to not damage the surface of my ring.