- Joined

- May 27, 2016

- Messages

- 3,479

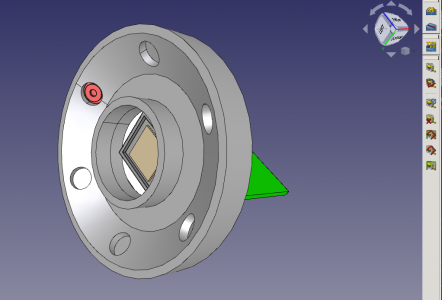

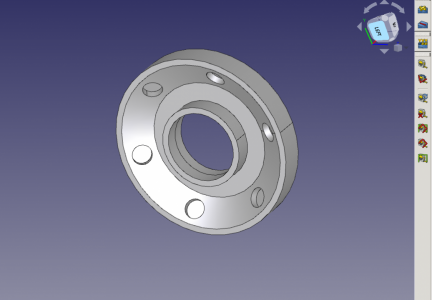

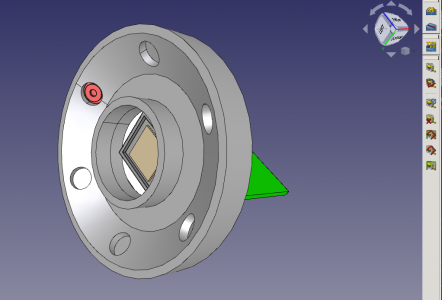

This is related to the XRF (X-ray Fluorescence) alloys identification project "Needing more than a spark test?" We have come to a point where it seems clear a sensor assembly concept using lead shielding is looking to be the one we need. I have tentatively have asked this sometime before, but I forgot when.

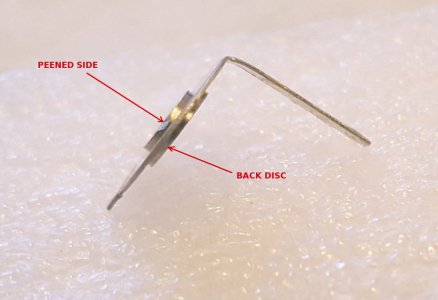

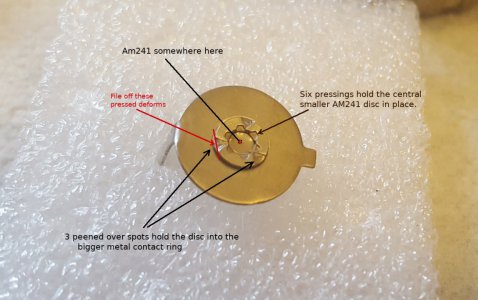

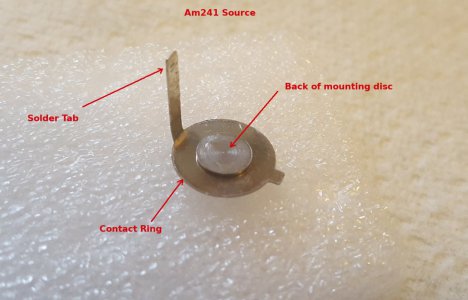

There are problems in even holding lead in a chuck. My guess is, do it carefully. Probably one has to melt some lead into the bottom of an ex-Red Bull can, to make a round lump to start with. The part has to be reasonably precision, such that the ex-smoke detector radioactive sources can be pressed into position, and stay there. No glue, loctite, nor any other substances other than the lead must be there. The gadget identifies elements, and the presence of other stuff just causes confusion.

.

.

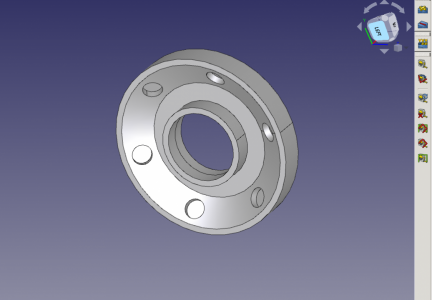

I start with wondering what shape the cutting tool should be. The diameter of the whole assembly is about 40mm (around 1.5 inches)

Any advice on making this would be appreciated.

There are problems in even holding lead in a chuck. My guess is, do it carefully. Probably one has to melt some lead into the bottom of an ex-Red Bull can, to make a round lump to start with. The part has to be reasonably precision, such that the ex-smoke detector radioactive sources can be pressed into position, and stay there. No glue, loctite, nor any other substances other than the lead must be there. The gadget identifies elements, and the presence of other stuff just causes confusion.

.

.

I start with wondering what shape the cutting tool should be. The diameter of the whole assembly is about 40mm (around 1.5 inches)

Any advice on making this would be appreciated.