- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

This is my first post. I am new to machining, and now working on my 4th small project. My primary goal is to make small, unobtainable parts for very old cars (pre-WW2).

I am using Sherline tools. I have the 4400 lathe and the 5400 mill.

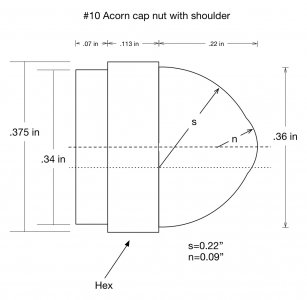

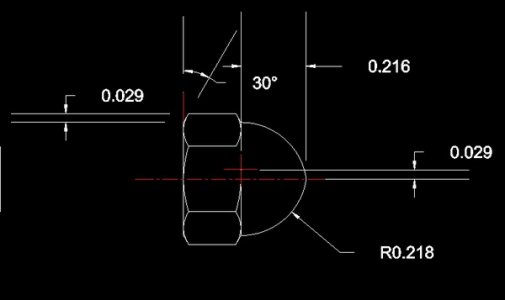

I am trying to make some #10 steel (1018) cap nuts with a shoulder that fits into a stabilizing counter bore. These are for 1930 Packard hinges. Standard cap nuts do not have the necessary shoulder.

My problem is that I have no idea how to machine the compound radius that makes up the dome of the nut.

I have the Sherline radius cutter, and have used it successfully on an earlier project with a simpler cut.

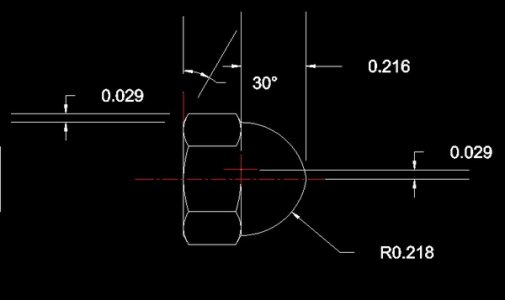

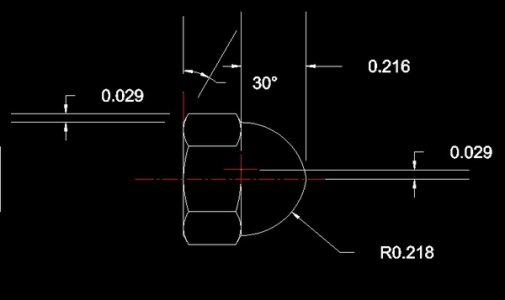

I have attached a diagram, modified from Machinery's Handbook, of the nut I am making. I removed the threads from the diagram for simplicity.

Any help will be greatly appreciated.

Thanks,

Tom

This is my first post. I am new to machining, and now working on my 4th small project. My primary goal is to make small, unobtainable parts for very old cars (pre-WW2).

I am using Sherline tools. I have the 4400 lathe and the 5400 mill.

I am trying to make some #10 steel (1018) cap nuts with a shoulder that fits into a stabilizing counter bore. These are for 1930 Packard hinges. Standard cap nuts do not have the necessary shoulder.

My problem is that I have no idea how to machine the compound radius that makes up the dome of the nut.

I have the Sherline radius cutter, and have used it successfully on an earlier project with a simpler cut.

I have attached a diagram, modified from Machinery's Handbook, of the nut I am making. I removed the threads from the diagram for simplicity.

Any help will be greatly appreciated.

Thanks,

Tom

that is why I hoped you had a idea. We were both on the same page just different paragraphs!

that is why I hoped you had a idea. We were both on the same page just different paragraphs!