- Joined

- Mar 26, 2018

- Messages

- 8,666

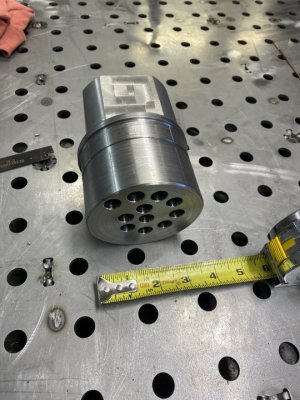

Loads of fun and lots of chips. I just finished the base, now on to the rest of the components.

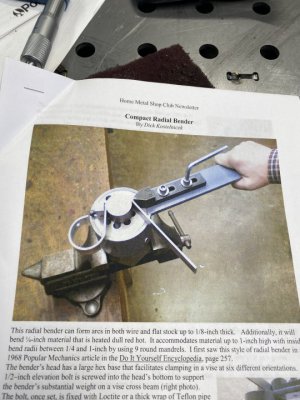

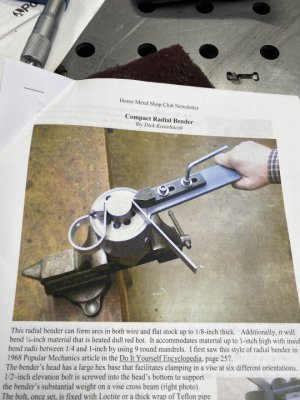

I got the idea from something I found on the web from, Home Metal Shop Club, Newsletter.

It should be a handy addition to the shop.

I got the idea from something I found on the web from, Home Metal Shop Club, Newsletter.

It should be a handy addition to the shop.

Attachments

-

9AA995A3-AEA9-4AC3-B37A-84D088CD6ABA.jpeg91.6 KB · Views: 133

9AA995A3-AEA9-4AC3-B37A-84D088CD6ABA.jpeg91.6 KB · Views: 133 -

BD5CD1A6-CBD2-4877-9B3B-2F44577B95E0.jpeg107.3 KB · Views: 121

BD5CD1A6-CBD2-4877-9B3B-2F44577B95E0.jpeg107.3 KB · Views: 121 -

EE19B248-88DD-4183-AC91-8D86456E2980.jpeg93.7 KB · Views: 98

EE19B248-88DD-4183-AC91-8D86456E2980.jpeg93.7 KB · Views: 98 -

C00050A8-C48B-4389-AC31-0EF8723A3260.jpeg121.8 KB · Views: 95

C00050A8-C48B-4389-AC31-0EF8723A3260.jpeg121.8 KB · Views: 95 -

8A0896A4-EF2C-4149-9CF6-A3C14B50E4B9.jpeg90.2 KB · Views: 89

8A0896A4-EF2C-4149-9CF6-A3C14B50E4B9.jpeg90.2 KB · Views: 89 -

157A8EFF-F72D-4C07-BB6E-1837E0464759.jpeg82.6 KB · Views: 84

157A8EFF-F72D-4C07-BB6E-1837E0464759.jpeg82.6 KB · Views: 84 -

42C3F6E8-47BA-4F54-B984-7D1C460AE345.jpeg118.1 KB · Views: 113

42C3F6E8-47BA-4F54-B984-7D1C460AE345.jpeg118.1 KB · Views: 113