Finally getting around to attempting a line bore on my counter shaft on Logan 820. (Post In Logan Forum) First I have to make the boring bar for my mill.

My counter shaft has a original hole size of 3/4 inch but is wobbled out by almost 1/8th of an inch on one side. I will be attempting to line bore to 1 inch.

My questions are these:

Size of Bar? I need to have a length of about 14 inches which will allow 2 cutters. For rigidity I was thinking of making the bar 3/4 inch to keep maximum rigidity but that will leave very little room for chip evacuation in the first few cuts. Should I reduce the size of the bar to a smaller diameter in the areas the cutters will be used to allow for chip clearance? How much clearance do I need?

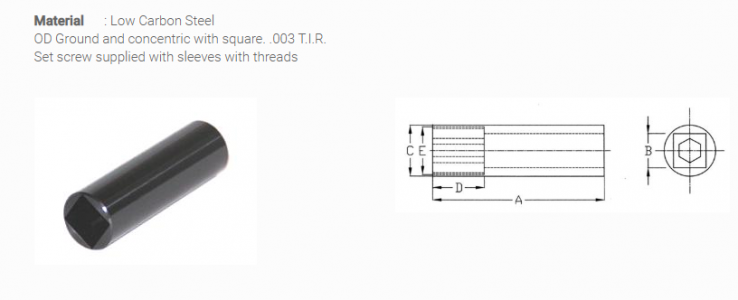

Cutters perpendicular to par or at an angle? As stated, I need two cutters. It would be easier to drill perpendicular to the bar and use a small grub screw to lock the cutters in place. If I do this there will be two holes on the very same plane making the bar less rigid? Or should I set cutters at an 45 degree angel with 90 degree offset grub screw. It would be more difficult to make but would it be stronger?

In 3/4 inch boring bar I was thinking of using 1/4 inch round drill rod for cutters with grub screws. It will be boring in cast Iron and may only get one use.

Thanks for your thoughts and suggestions.

My counter shaft has a original hole size of 3/4 inch but is wobbled out by almost 1/8th of an inch on one side. I will be attempting to line bore to 1 inch.

My questions are these:

Size of Bar? I need to have a length of about 14 inches which will allow 2 cutters. For rigidity I was thinking of making the bar 3/4 inch to keep maximum rigidity but that will leave very little room for chip evacuation in the first few cuts. Should I reduce the size of the bar to a smaller diameter in the areas the cutters will be used to allow for chip clearance? How much clearance do I need?

Cutters perpendicular to par or at an angle? As stated, I need two cutters. It would be easier to drill perpendicular to the bar and use a small grub screw to lock the cutters in place. If I do this there will be two holes on the very same plane making the bar less rigid? Or should I set cutters at an 45 degree angel with 90 degree offset grub screw. It would be more difficult to make but would it be stronger?

In 3/4 inch boring bar I was thinking of using 1/4 inch round drill rod for cutters with grub screws. It will be boring in cast Iron and may only get one use.

Thanks for your thoughts and suggestions.