- Joined

- May 7, 2020

- Messages

- 267

We want to make metal finishing easier without having to buy one of those giant conveyor belt style sanders - the ones that cost a mint and eat up all the space in a garage shop.

Something like this Time Saver above - not gonna happen. And a precision surface grinder is not a good way to make the kind of brushed surface finish we're looking for (and way too small for anything close to reasonable money).

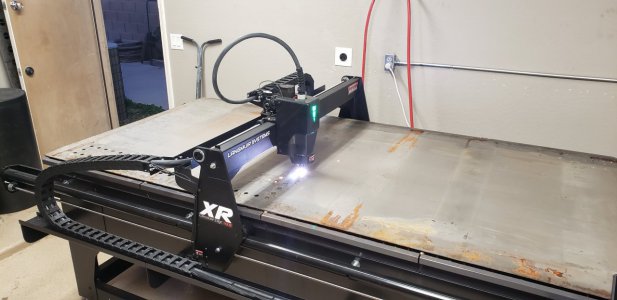

First step is to adapt our downdraft table for a smaller, hand-held metal finishing tool like this Walter. The idea is to replace the stainless steel top on the downdraft with something custom made that will allow us mount electro-magnets flush with the work surface. We don't want to chase the workpiece around the table or ruin the finish. We'll design the new top in F360 and then fabricate on the CNC plasma.

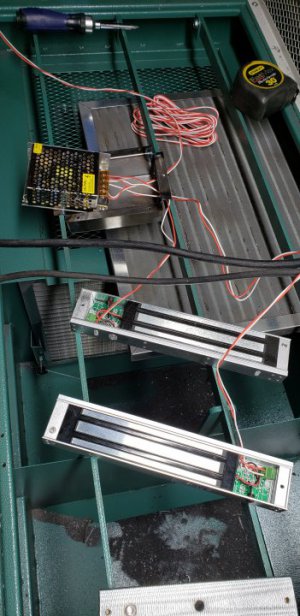

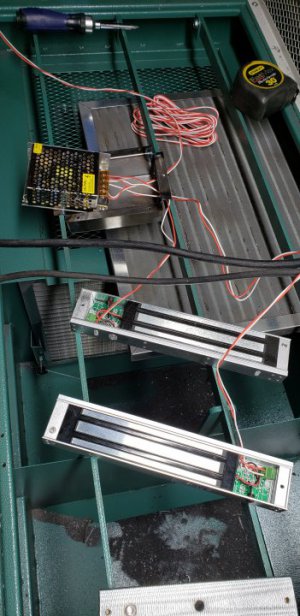

We're trying out magnets used for security doors (when they buzz you in). Open to ideas though. Cheap and don't take much power - but the fit does need to be flush. We wired a power supply into the main power switch on the table. Will put another witch on the circuit when we don't need magnetizationing.

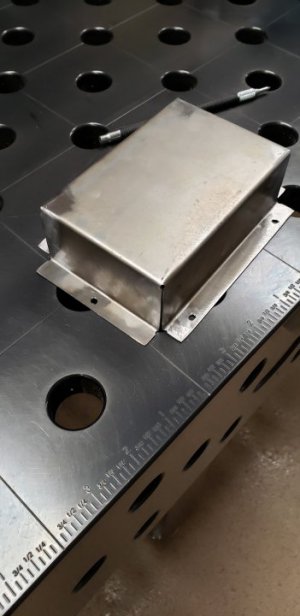

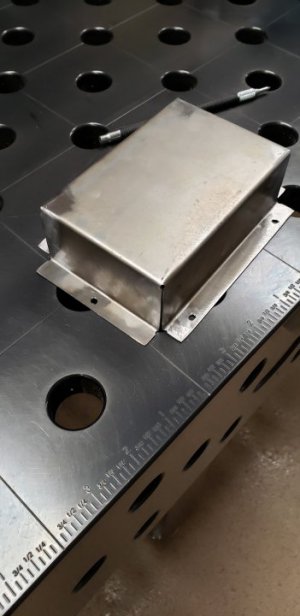

Needed a box for the power supply - pretty harsh environment for electronics inside that table. Gave us a chance to try out the new pan brake (Grizzly G0542). Bending is important in metal fabrication and we just don't have the space for a proper commercial press brake. Pretty happy with this Grizzly (obviously Chinesium but not horrible). Will bend up to 12 gauge and 20 gauge is laughably easy. Fit and finish is pretty good on the parts that matter and typical on the parts that don't. Best of all, very quick and efficient for one-off work which is closer to what we do.

Technically not capable of reverse bends on two axes but we forced the issue a bit. Not terrible for our first go on sheet metal bending I think.

More to come as we run our little science experiment.

Something like this Time Saver above - not gonna happen. And a precision surface grinder is not a good way to make the kind of brushed surface finish we're looking for (and way too small for anything close to reasonable money).

First step is to adapt our downdraft table for a smaller, hand-held metal finishing tool like this Walter. The idea is to replace the stainless steel top on the downdraft with something custom made that will allow us mount electro-magnets flush with the work surface. We don't want to chase the workpiece around the table or ruin the finish. We'll design the new top in F360 and then fabricate on the CNC plasma.

We're trying out magnets used for security doors (when they buzz you in). Open to ideas though. Cheap and don't take much power - but the fit does need to be flush. We wired a power supply into the main power switch on the table. Will put another witch on the circuit when we don't need magnetizationing.

Needed a box for the power supply - pretty harsh environment for electronics inside that table. Gave us a chance to try out the new pan brake (Grizzly G0542). Bending is important in metal fabrication and we just don't have the space for a proper commercial press brake. Pretty happy with this Grizzly (obviously Chinesium but not horrible). Will bend up to 12 gauge and 20 gauge is laughably easy. Fit and finish is pretty good on the parts that matter and typical on the parts that don't. Best of all, very quick and efficient for one-off work which is closer to what we do.

Technically not capable of reverse bends on two axes but we forced the issue a bit. Not terrible for our first go on sheet metal bending I think.

More to come as we run our little science experiment.

Last edited: