- Joined

- Dec 27, 2021

- Messages

- 15

I've bought a different lathe a few weeks ago and i made a TDI for my previous lathe also.

I really think a TDI is great when you need to cut threads on the lathe.

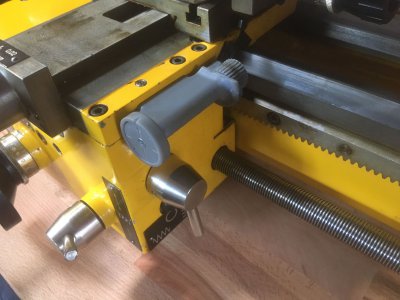

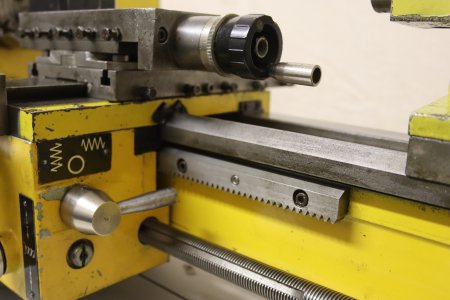

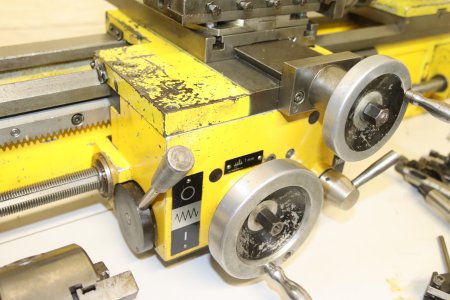

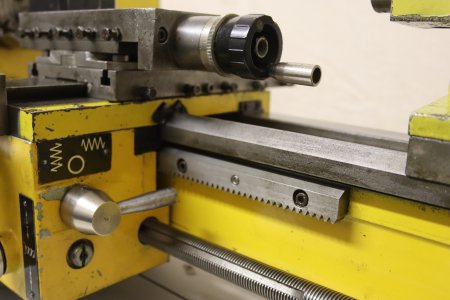

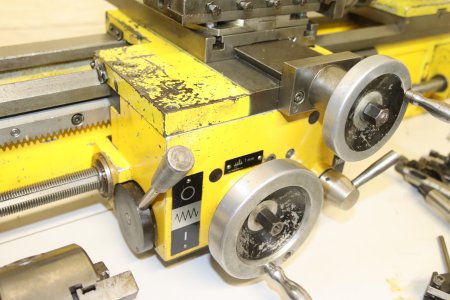

My lathe is a Prazimat DLZ450x180 and on both sides of the carriage are handles located.

On the back a handle to change between autofeed for the carriage and the crossslide and on the front of the carriage the handle to engage the autofeed.

(Both images are from the internet)

But because of the handles I thought it would be nice to have a TDI that you can remove easily.

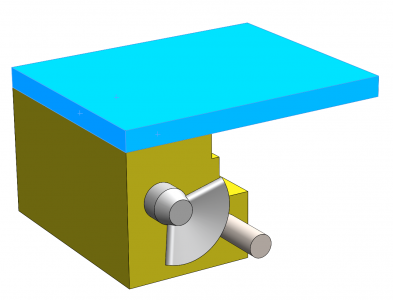

After that i started thinking of a way to mount the TDI and i thought that a large magnet would be great for this setup.

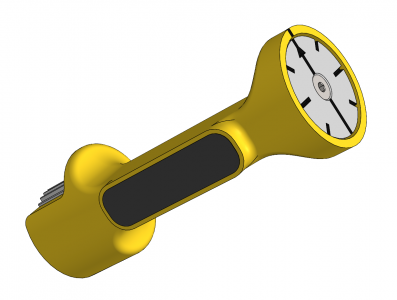

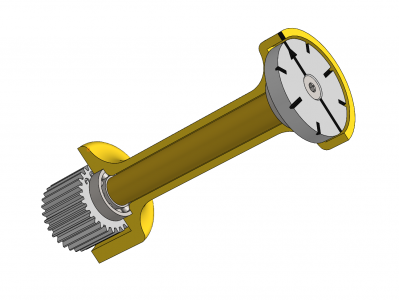

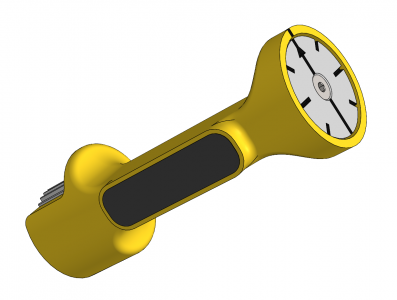

In the images below you can find the design: Behind the black rubber there is a 30x10x4 Neodymium magnet and I added 2 bearings to support the shaft.

In the pictures below you can find the first proove of concept which is printed on a formlabs printer.

I think I will try this one out on the lathe next weekend.

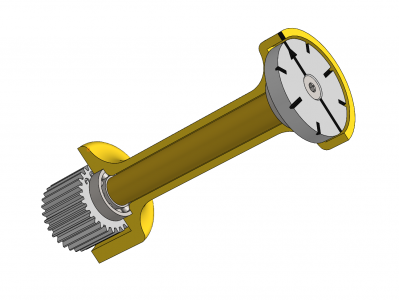

The final version will also have several printed parts: the housing, the gears (28T and 30T) and the dial.

The other pieces will be turned and machined on my lathe and milling machine.

I really think a TDI is great when you need to cut threads on the lathe.

My lathe is a Prazimat DLZ450x180 and on both sides of the carriage are handles located.

On the back a handle to change between autofeed for the carriage and the crossslide and on the front of the carriage the handle to engage the autofeed.

(Both images are from the internet)

But because of the handles I thought it would be nice to have a TDI that you can remove easily.

After that i started thinking of a way to mount the TDI and i thought that a large magnet would be great for this setup.

In the images below you can find the design: Behind the black rubber there is a 30x10x4 Neodymium magnet and I added 2 bearings to support the shaft.

In the pictures below you can find the first proove of concept which is printed on a formlabs printer.

I think I will try this one out on the lathe next weekend.

The final version will also have several printed parts: the housing, the gears (28T and 30T) and the dial.

The other pieces will be turned and machined on my lathe and milling machine.

Attachments

Last edited: