- Joined

- Mar 26, 2018

- Messages

- 8,666

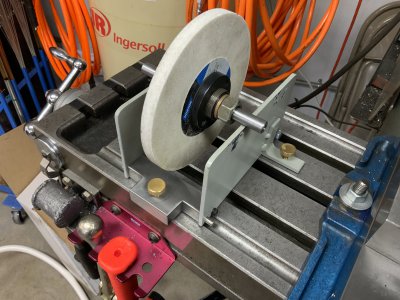

Setting the angle for the Sopko adapters wasn’t as easy as I originally thought.

The spec is 3” per foot. In my simple mind, I would set up the compound to .250” per inch. That is wrong!!

.250 X 12 is 3. At least that’s the way I figure.

So I did some snooping on the internet. I found a thread in Practical machinist where it is said to set the compound to half that amount.

Hugh? So, I set the compound to .125” of movement over one inch.

The proof is in the pudding as it were.

Is it because it’s half the angle?

Hey, the arbor locks up tight in the adapter. It works slick.

I couldn’t hold it upside down and take the picture at the same time. Trust me, it locks up nice.

The spec is 3” per foot. In my simple mind, I would set up the compound to .250” per inch. That is wrong!!

.250 X 12 is 3. At least that’s the way I figure.

So I did some snooping on the internet. I found a thread in Practical machinist where it is said to set the compound to half that amount.

Hugh? So, I set the compound to .125” of movement over one inch.

The proof is in the pudding as it were.

Is it because it’s half the angle?

Hey, the arbor locks up tight in the adapter. It works slick.

I couldn’t hold it upside down and take the picture at the same time. Trust me, it locks up nice.