- Joined

- Dec 18, 2019

- Messages

- 7,426

No surprise to most everyone here, my mini-lathe isn't in alignment. I cut a simple 6061 rod, trimmed it to diameter and drilled a hole in it using the lathe. I then tapped the hole by hand. The screw is loose. Now, I've used this 8-32 tap before, just a few days ago, and it cut a decent set of threads, that were ok. (Slightly loose) The difference is in one case, I used my lathe to drill the hole, and in the earlier case, I used a drill press. I used the same #29 drill. The lathe drilled hole is larger diameter than it should be.

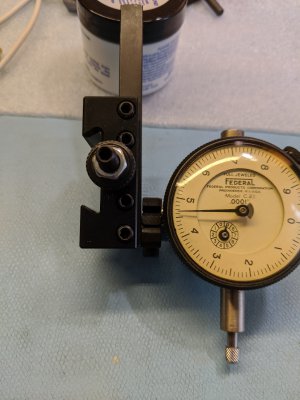

So I checked the alignment of a MT3 dead center in the spindle and a MT2 dead center in the tail stock and they seem to be kind of far apart. Like guesstimating 0.01" in height and about the same in displacement. It's noticeable by eye. It seems that the tail stock is higher than the spindle, which from reading - isn't good. By that I mean, I can't shim the tail stock and be done with it.

I found this thread https://www.hobby-machinist.com/threads/mini-lathe-tailstock-alignment.30208/ by @petcnc on this subject. I've read it about 4 times now, each time understanding a little bit more. I thought I had access to the lower adjusting bolt #1, but I just don't have a long enough 4mm key to be able to really tighten and loosen it effectively while the tail stock is on the ways. So I think I'll have to do some of his modifications.

Reflecting on this, I don't actually know that my spindle is aligned to the ways correctly. How can I check that?

Assuming that it's close enough, then I should proceed with the thread above?

Down the rabbit hole I go...

So I checked the alignment of a MT3 dead center in the spindle and a MT2 dead center in the tail stock and they seem to be kind of far apart. Like guesstimating 0.01" in height and about the same in displacement. It's noticeable by eye. It seems that the tail stock is higher than the spindle, which from reading - isn't good. By that I mean, I can't shim the tail stock and be done with it.

I found this thread https://www.hobby-machinist.com/threads/mini-lathe-tailstock-alignment.30208/ by @petcnc on this subject. I've read it about 4 times now, each time understanding a little bit more. I thought I had access to the lower adjusting bolt #1, but I just don't have a long enough 4mm key to be able to really tighten and loosen it effectively while the tail stock is on the ways. So I think I'll have to do some of his modifications.

Reflecting on this, I don't actually know that my spindle is aligned to the ways correctly. How can I check that?

Assuming that it's close enough, then I should proceed with the thread above?

Down the rabbit hole I go...