I got tired of the 11mm wrench pretty quick so I took inspiration from around the web and made a ugly prototype drawbar. I am super happy with the results. Next on the list is to machine a nice combo bracket for the the drawbar and encoder and some cable/hose management.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Made a Power Drawbar for the PM728

- Thread starter GB21

- Start date

- Joined

- Jan 26, 2021

- Messages

- 345

That looks like it works consistently. Nice

- Joined

- Dec 26, 2015

- Messages

- 2,139

Looks great if you're comfortable with TSS toolholder for everything. I like it.

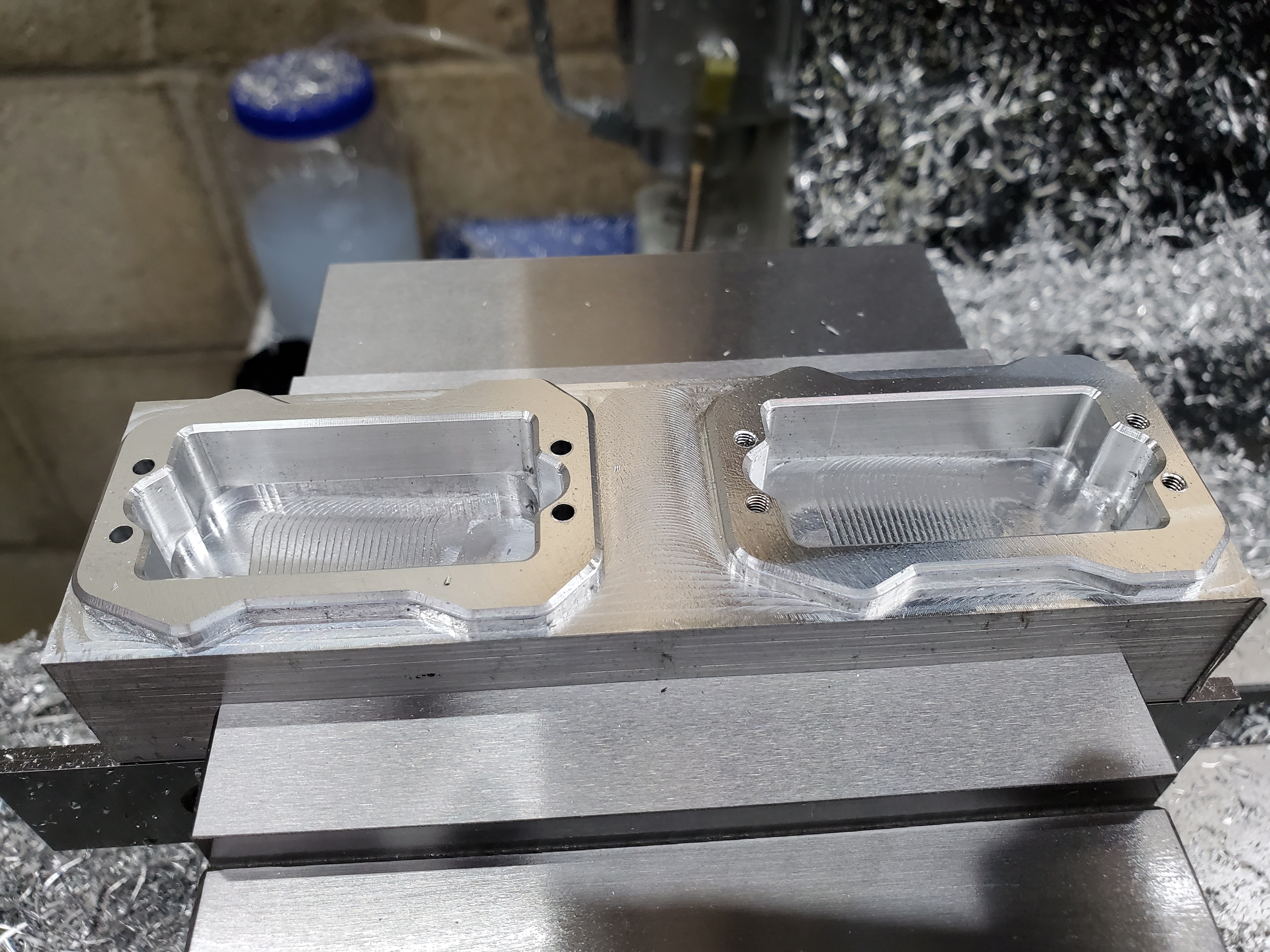

First failure.I was running a 3/8 endmill pretty hard you can see the angle in the bottom of the pocket where the tool was pulling out. Good thing I caught it before I had a catastrophic failure. The working load of the spring washers is 1890lbs. I watched a video saying the tormach machines are running 2700lbs I am going to try to get closer to that and see what happens.

- Joined

- Dec 26, 2015

- Messages

- 2,139

Not sure if you've seen this, but at 1:40 in the timeline he's dealing with the Belleville washer pull power issue:

- Joined

- Jan 7, 2016

- Messages

- 3,379

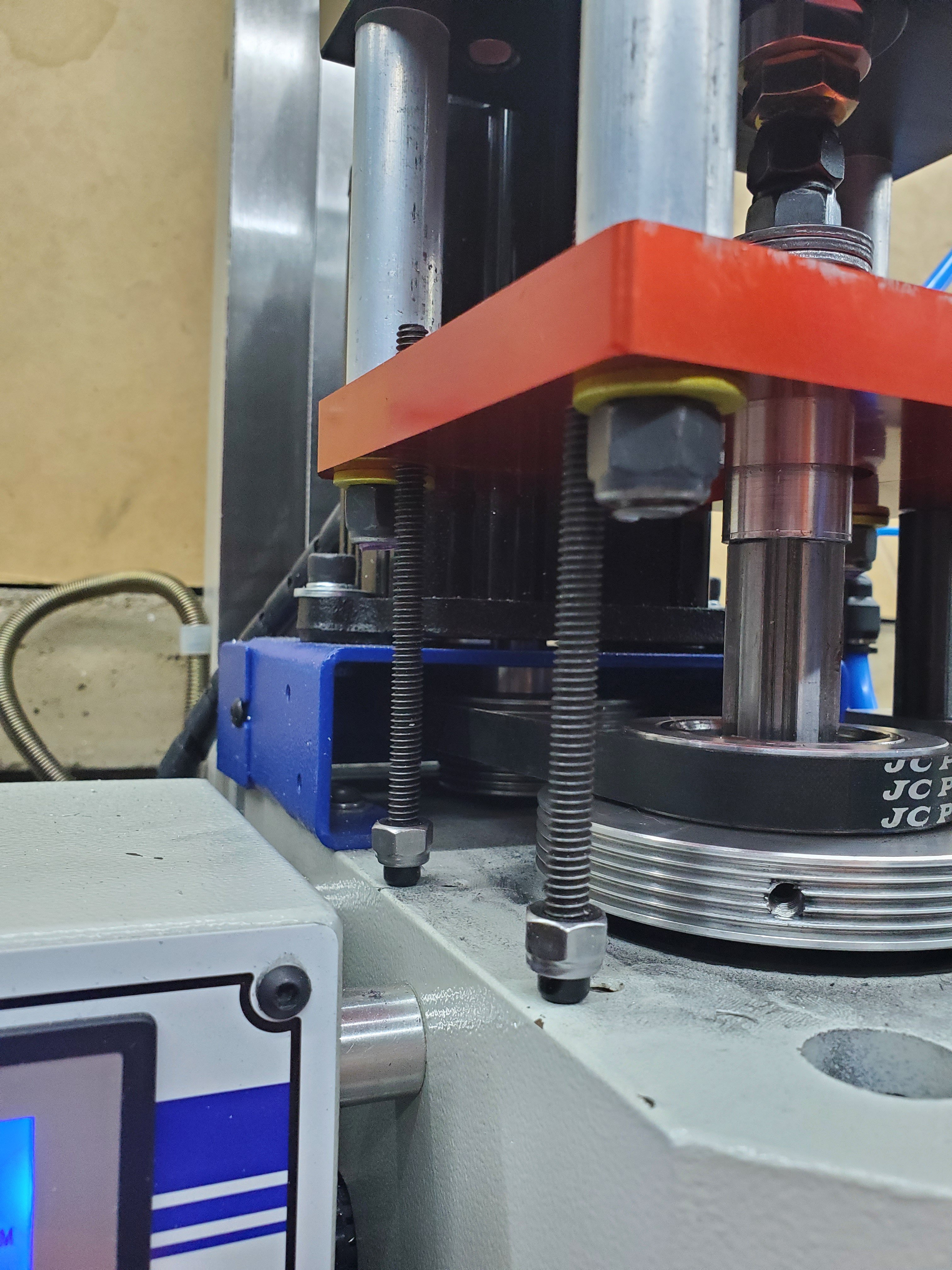

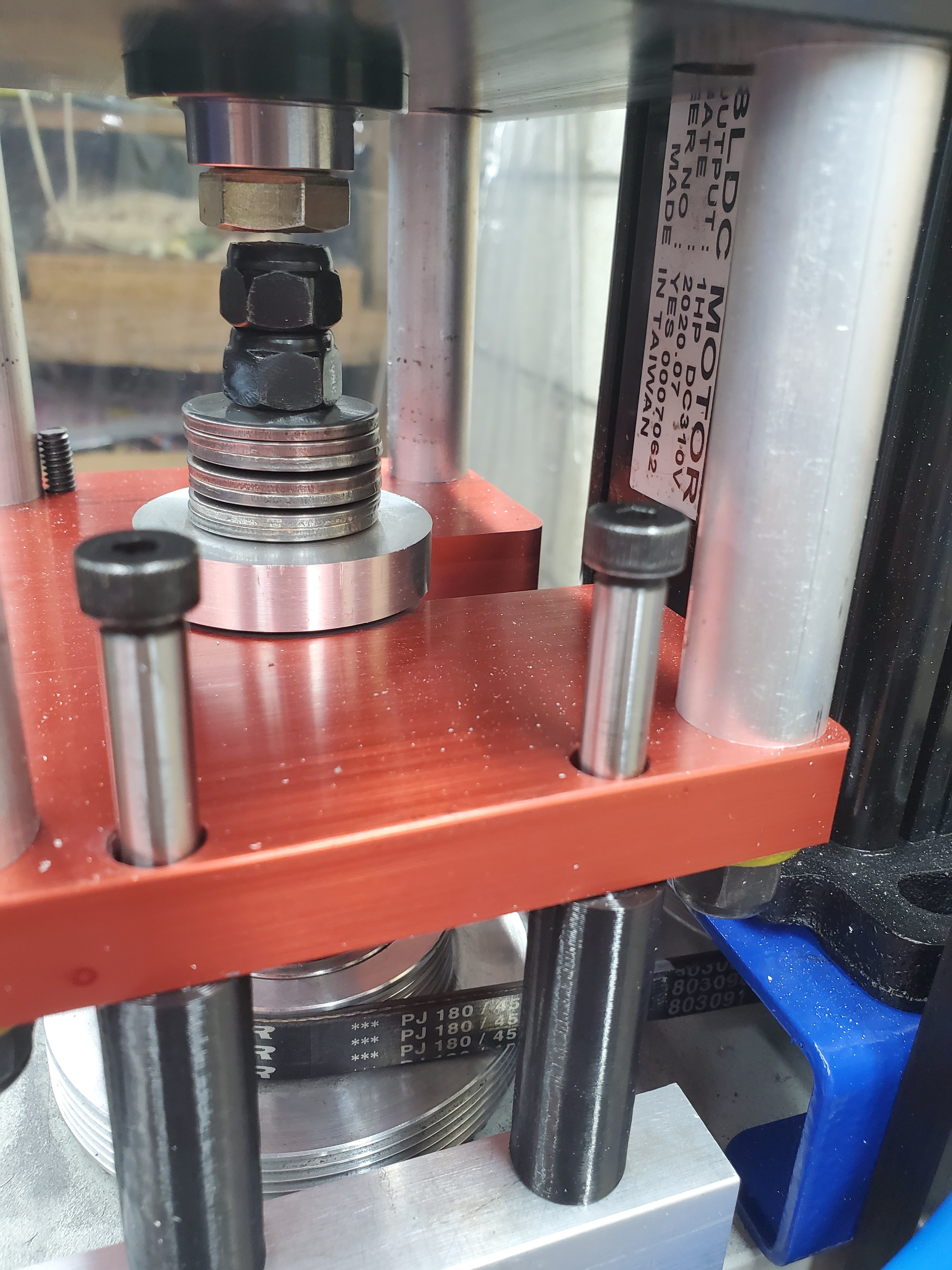

What size of air cylinder did you use on that? I have a number of them lying around...I got tired of the 11mm wrench pretty quick so I took inspiration from around the web and made a ugly prototype drawbar. I am super happy with the results. Next on the list is to machine a nice combo bracket for the the drawbar and encoder and some cable/hose management.

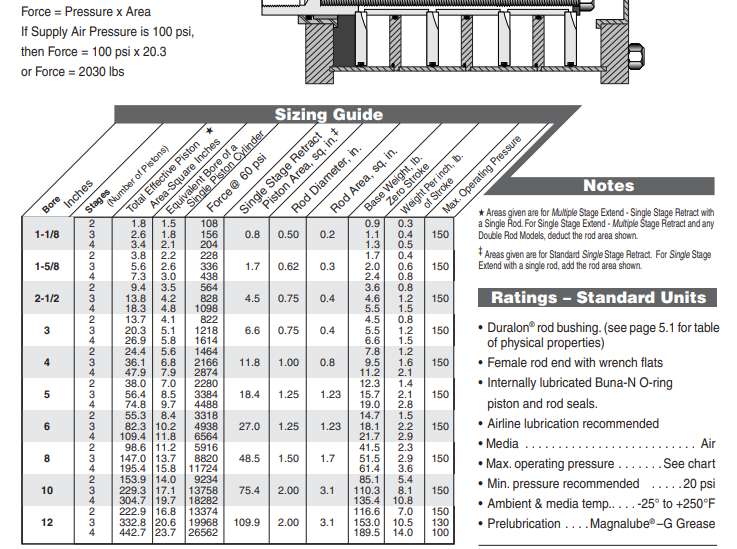

Fabco 4" 2 stage. It barely fits without modification, I actually had to remove the fan cover from the motor to center the piston. A multi stage cylinder is a must in my opinion. Here is a chart I found useful when trying to figure out what size I needed.

Sorry for the late response I have been a little busy. Mcmaster springs # 9712K436.

I used 3/8" b7 threaded rod for the mount with aluminum tube I found in my scrap bin.The shoulder bolts are 5/16" Diameter 1/4"-20 Thread with 3d printed spacers. The other side I used 1/4" allthread with nylon-cap locknuts. For the drawbar I used grade 8 allthread with double high strength locknuts. (Too lazy to get the welder out). For a switch I am using a cheap foot pedal I picked up on amazon for like 18 bucks (tailonz 4F210-08) works great no leaks yet.

I was trying to keep everything simple in case anything did not work. Turns out everything is working perfect and I have not had to make any changes yet although like I said I will be remaking the shoulder bolt mount a little nicer and to fit a encoder and add more room for the belt.

I used 3/8" b7 threaded rod for the mount with aluminum tube I found in my scrap bin.The shoulder bolts are 5/16" Diameter 1/4"-20 Thread with 3d printed spacers. The other side I used 1/4" allthread with nylon-cap locknuts. For the drawbar I used grade 8 allthread with double high strength locknuts. (Too lazy to get the welder out). For a switch I am using a cheap foot pedal I picked up on amazon for like 18 bucks (tailonz 4F210-08) works great no leaks yet.

I was trying to keep everything simple in case anything did not work. Turns out everything is working perfect and I have not had to make any changes yet although like I said I will be remaking the shoulder bolt mount a little nicer and to fit a encoder and add more room for the belt.

Last edited: