- Joined

- Jul 15, 2020

- Messages

- 422

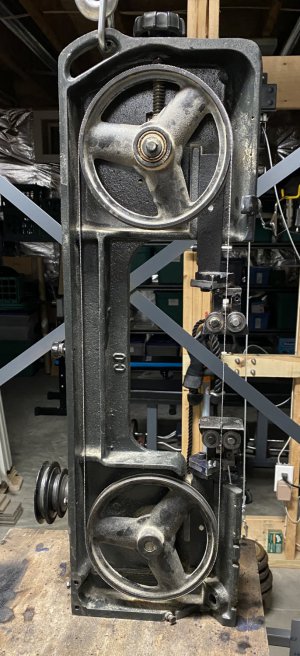

Since I bought my 7" x 12" Jet horizontal bandsaw, my little 4 x 6 has been sitting idle. I decided to make a sturdy table for it so I could do some vertical sawing.

I decided that the simplest approach was to use some 1/4" mild steel plate for a base and a table, and some 4" x 4" x 1/4" thick angle iron for a column. I drilled two 3/8" diameter holes in the saw frame to bolt the base down. The result is an extremely rigid table that could be removed for horizontal sawing (or blade changes) in seconds by removing the two bolts. I plan to use it pretty much for vertical sawing however.

I decided that the simplest approach was to use some 1/4" mild steel plate for a base and a table, and some 4" x 4" x 1/4" thick angle iron for a column. I drilled two 3/8" diameter holes in the saw frame to bolt the base down. The result is an extremely rigid table that could be removed for horizontal sawing (or blade changes) in seconds by removing the two bolts. I plan to use it pretty much for vertical sawing however.

Last edited: