Greetings,

I am trying to make an ejection system for my small aluminum molds with my Taig Mill, similar to what Mr. Socha does in this video (specifically the mold shown during 2:50 - 4:46):

While his mold and ejection pins are made out of brass, he mentions that perhaps brass is not an optimal material for the pins because the pin surface will gall easily. My subsequent thought was to use steel instead.

My initial plan was to buy O1 Precision Rod (from eBay), but I don't think I have the equipment to cut it to length accurately (I don't have a lathe). The tolerance of the length needs to be within .001”.

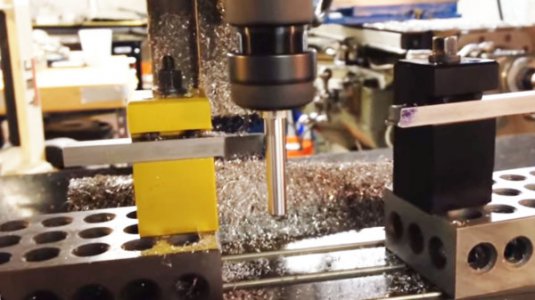

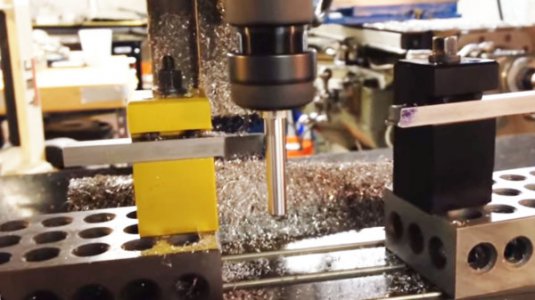

I thought about cutting the O1 rod close to length with a cutting wheel, then parting it off to length with the stock held in my mill's collet like in this image:

But I think cutting O1 might require rigidity that my mini mill does not have. Perhaps I'm mistaken?

My next and current plan is to use cold-rolled steel at 3/16” diameter and turn it down to 1/8” with HSS tools.

Do you think my plan is good? Maybe brass or aluminum ejection pins would suffice? If I need to go with steel I would prefer to use the O1 precision rod, but I don't have the means to cut it to length accurately.

Machine Details:

Taig CNC Mill with Ballscrews.

1/4 HP spindle motor

RPM Options: 1050, 1650, 2600, 4200, 6700, 10600

Any advice would be appreciated!

- Mike

I am trying to make an ejection system for my small aluminum molds with my Taig Mill, similar to what Mr. Socha does in this video (specifically the mold shown during 2:50 - 4:46):

While his mold and ejection pins are made out of brass, he mentions that perhaps brass is not an optimal material for the pins because the pin surface will gall easily. My subsequent thought was to use steel instead.

My initial plan was to buy O1 Precision Rod (from eBay), but I don't think I have the equipment to cut it to length accurately (I don't have a lathe). The tolerance of the length needs to be within .001”.

I thought about cutting the O1 rod close to length with a cutting wheel, then parting it off to length with the stock held in my mill's collet like in this image:

But I think cutting O1 might require rigidity that my mini mill does not have. Perhaps I'm mistaken?

My next and current plan is to use cold-rolled steel at 3/16” diameter and turn it down to 1/8” with HSS tools.

Do you think my plan is good? Maybe brass or aluminum ejection pins would suffice? If I need to go with steel I would prefer to use the O1 precision rod, but I don't have the means to cut it to length accurately.

Machine Details:

Taig CNC Mill with Ballscrews.

1/4 HP spindle motor

RPM Options: 1050, 1650, 2600, 4200, 6700, 10600

Any advice would be appreciated!

- Mike