The 6x6 plate worked okay as a "proof of concept". I learned three things.

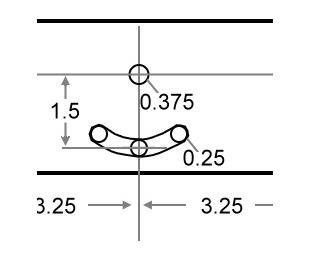

1. I need to machine a center pin (probably several in various diameters) to ensure repeatability.

2. Phillips head machine screws countersunk flush make for easy mounting but are difficult, if not impossible to get tight enough to stay tight.

3. 1/4-20 square nuts worked in a pinch, but I need to make some actual t-nuts to fit the slots on the table.

The intermediate plate got loose halfway through machining the slot and reproducing the setup after tightening the screws didn't work very well. I probably could have gotten close enough if I had fussed with it long enough, but it was just a test piece that didn't matter anyway and by that time I'd figured out what needed to be done on the actual piece.

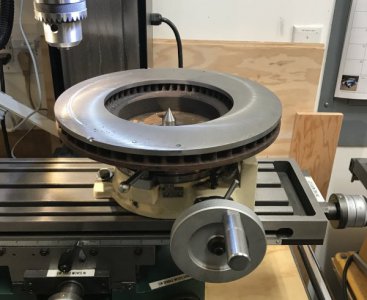

The disc brake idea is cool, but a little overwhelming for my iddy-biddy 3" table...

I need to scrounge up a piece of 1/2" aluminum to make Part Deux so I can counter-sink some hex-head bolts for hold-downs.