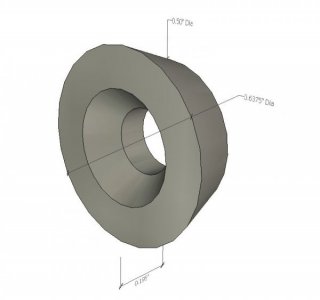

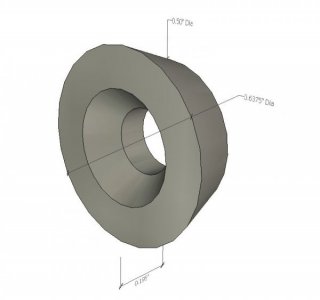

Hello and Happy New Year! Newbie here. I'm trying to make a tapered insert with a through-hole that is used to secure a circular seal. The taper is 20 degrees; the small end is 0.5" diameter and the larger end is 0.64" diameter. Depth is just under 0.2”.

I've made a couple - one out of Delrin and one from aluminum. The way I did that was to turn the taper (small end away from the chuck), drill the through-hole, and then cut-off the part at the larger face. Here's where I run into my problem. I need to drill a countersink for a screw head on the larger face, and I can't come up with the proper method to do that. As the part is rather small, I have a hard time securing it on my drill press. I've resorted to holding it by hand (not the safest alternative, I know) while drilling the countersink. More easily done on Delrin than aluminum, but not precise by any means.

Is there a way to "reverse" taper (smaller end on the chuck side)? That would seem to require an awful lot of extra material removal for tool clearance, but maybe I'm missing something. Maybe there's a better way to secure the part on drill press? I've attached a drawing of the part as well as a couple of photos showing the completed part. Any suggestions would be appreciated!

I've made a couple - one out of Delrin and one from aluminum. The way I did that was to turn the taper (small end away from the chuck), drill the through-hole, and then cut-off the part at the larger face. Here's where I run into my problem. I need to drill a countersink for a screw head on the larger face, and I can't come up with the proper method to do that. As the part is rather small, I have a hard time securing it on my drill press. I've resorted to holding it by hand (not the safest alternative, I know) while drilling the countersink. More easily done on Delrin than aluminum, but not precise by any means.

Is there a way to "reverse" taper (smaller end on the chuck side)? That would seem to require an awful lot of extra material removal for tool clearance, but maybe I'm missing something. Maybe there's a better way to secure the part on drill press? I've attached a drawing of the part as well as a couple of photos showing the completed part. Any suggestions would be appreciated!