I have South Bend Lathe # 1248TKL9. It is a 13" lathe that shipped between 4/22/47 & 5/27/47, and has seen a lot of use. I have owned it for the last 12 years, of which the last 9 were spent in storage. For as long as I used it, I always had trouble with my parts OD having a taper, and the face being convex. I had concluded that I simply was doing something very wrong. That is partly why I let it languish in storage so long. A few months ago, I was finally able get the time and nerve to begin to put my shop together to get active in metal working again. Lurking around here, I began to suspect that the issue might be the lathe and not me.

Not knowing how to scrape or having experience with rebuilding machines (yet) :whistle:, I started researching getting the ways ground. Based upon Richard's (King) high recommendation of them, I selected Schimede Corp in Tullahoma, TN to do it.

I e-mailed the Sales Manger listed on their website, and the Shop Foreman, Doug VonFossen responded the following day. When he found out that I was planning on driving there from South Carolina to drop it off and pick it up, he volunteered to have it worked by both shifts so that I would be ready for me to pick up the next day if I got to them before 8 am, and therefore not have to make two trips. They e-mailed the quote to me in PDF form, and the price was good for 3 months. He said to call him when I got there and give him my CC number and they would start the paperwork for me.

I called him Friday and told him I would be there Monday morning. When I arrived, the Shipping Clerk met me in the parking lot and guided me to the Machinist that would be doing the ways when he found out which machine I was delivering. He had me back my truck through the building right to the front of the way grinder, and the machinist, Dwight, helped me unload and unpack the parts. Doug (VanFossen) showed up in a couple minutes and helped also. We got to talking and he offered to give me a tour of the facility. We went through 5 of the 6 buildings, only not seeing the the Welding Shop. I got to look closely at several of their jobs, parts, and machines. Some of the machinists brought me pictures of their work. They had several machines in various stages of rebuild, along with many aircraft parts, and tooling mounts being made. I got to talk with a couple of their machine rebuilders at length about what they were doing to the machines they were currently working on, and about scraping. I also spent about a hour working along side Dwight as he ground the bed of my lathe. They also gave me some Tursite & glue for the cross-slide, and a couple feet of 1" drill rod to use to align the head-stock when I reassemble the lathe. BTW, they told me that the problem was definitely the lathe. hew:

hew:

I was unable to take any pictures as they strictly forbid cameras and cell phones with cameras in their shop. However, they do have pictures on their website. The shop buildings are very clean and well lit. The employees seem to be proud of their work and all of the ones I dwelt with have been with the company for many years.

Here are pictures of my lathe parts from before they worked on them:

And after:

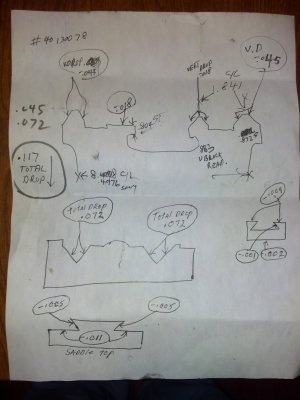

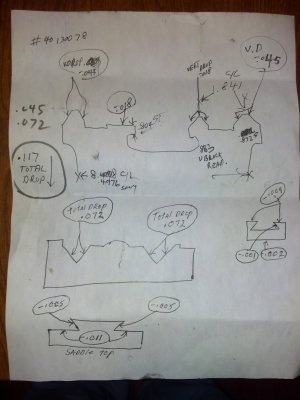

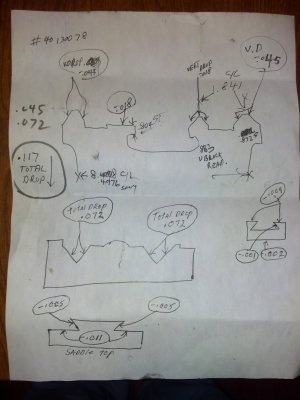

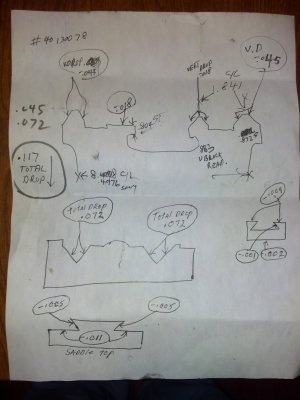

And here is the diagram Dwight drew up for me listing what was removed (I especially like that he listed drop instead of amount removed on the v-ways. My trig is not what it used to be.):

I am very pleased with their work and exceptional customer service. I highly recommend them to anyone needing work done.

Thanks, Richard for steering me their way.

Not knowing how to scrape or having experience with rebuilding machines (yet) :whistle:, I started researching getting the ways ground. Based upon Richard's (King) high recommendation of them, I selected Schimede Corp in Tullahoma, TN to do it.

I e-mailed the Sales Manger listed on their website, and the Shop Foreman, Doug VonFossen responded the following day. When he found out that I was planning on driving there from South Carolina to drop it off and pick it up, he volunteered to have it worked by both shifts so that I would be ready for me to pick up the next day if I got to them before 8 am, and therefore not have to make two trips. They e-mailed the quote to me in PDF form, and the price was good for 3 months. He said to call him when I got there and give him my CC number and they would start the paperwork for me.

I called him Friday and told him I would be there Monday morning. When I arrived, the Shipping Clerk met me in the parking lot and guided me to the Machinist that would be doing the ways when he found out which machine I was delivering. He had me back my truck through the building right to the front of the way grinder, and the machinist, Dwight, helped me unload and unpack the parts. Doug (VanFossen) showed up in a couple minutes and helped also. We got to talking and he offered to give me a tour of the facility. We went through 5 of the 6 buildings, only not seeing the the Welding Shop. I got to look closely at several of their jobs, parts, and machines. Some of the machinists brought me pictures of their work. They had several machines in various stages of rebuild, along with many aircraft parts, and tooling mounts being made. I got to talk with a couple of their machine rebuilders at length about what they were doing to the machines they were currently working on, and about scraping. I also spent about a hour working along side Dwight as he ground the bed of my lathe. They also gave me some Tursite & glue for the cross-slide, and a couple feet of 1" drill rod to use to align the head-stock when I reassemble the lathe. BTW, they told me that the problem was definitely the lathe.

I was unable to take any pictures as they strictly forbid cameras and cell phones with cameras in their shop. However, they do have pictures on their website. The shop buildings are very clean and well lit. The employees seem to be proud of their work and all of the ones I dwelt with have been with the company for many years.

Here are pictures of my lathe parts from before they worked on them:

And after:

And here is the diagram Dwight drew up for me listing what was removed (I especially like that he listed drop instead of amount removed on the v-ways. My trig is not what it used to be.):

I am very pleased with their work and exceptional customer service. I highly recommend them to anyone needing work done.

Thanks, Richard for steering me their way.