- Joined

- May 7, 2014

- Messages

- 776

I found the note below from Jumps4 when searching around on my issue. Maybe someone can confirm if the Mach3 version for RPM is real?

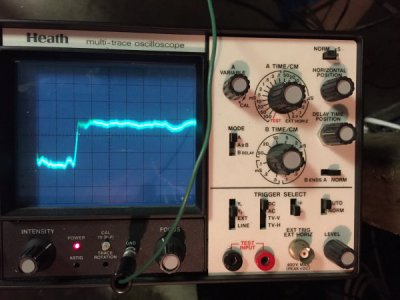

Issue: GekoG540. I have a regular ol' Opto Switch currently installed w/ reflective tape on the lathe pully. This setup also requires yet another 5v power supply. The design is setup to put the signal into pin 1 of the G540. It does not seem to be working. (Checking on my OScope). Before I go and mess with an Opto setup, Does anyone have a preference? Opto's -vs- Proximity's rated?

I read about how slow opto's are and on the flip side, the proximity's are rated in how fast they can run?

Q1) Is there anything in all this for a simple MAch3 turn setup? No need for overkill, but we would like to be more accurate than less and none of these seem all that expensive.

Q2) I read the G540 inputs are internally pulled to +12V and trigger as edge low as an input? But I am still just picking notes here and there off forums. Do we have some specifics about the G540 inputs and are folks using them as Vcc for the opto-transistor switch? Someone have something elegant for a pulse here off the pulley?

The setup that came w/ my unit has: 1- 220Ohm resister on the Vcc side of the emitter diode. On the transistor (pulse out) they had emitter to ground and collector to Pin 1 on the Gecko.

anyway- Before I go change this up and even bother with it.... What's out there as a quick hit, bolt and go. For 5-10 bucks I just do not have the time to play with so many projects going on.

Some sample optek circuits. ( I have a few optek sensors I bought to do the Mill spindle so I can experiment). Here are the 2 designs - common collector and common emitter outputs. Thought I would pass on the info. It's a good PDF for simply photo on/off stuff.

http://optekinc.com/pdf/app bulletin 213-opto assemblies.pdf

Anyway, Thanks as always- time to learn the lathe and get into turning!

From Jumps4: Mach3 version specific for RPM and turn to do threads:

in mach3 turn threading can only be done on a breakout board using a parallel port as far as I know. a uc100 usb will not work and I'm not sure any other usb or ethernet cards thread.

mach3 needs to be an older version the latest version does not work ( I'll try to see what version I'm running and send it to you )

pins 10,11,12,13 and 15 are input pins on the breakout board, use what ever one your not using for homing and limit swiches that is left. and on the configuration input screen set that breakout board pin number as the "index"

you can only use one pulse per revolution.

here is a good mach3 pdf to help you out ( http://www.machsupport.com/wp-content/uploads/2013/02/Mach3_Threading.pdf )

threading works best a low speed in mach3 usually not above 150

other people have other results but mach3 turn has never worked correctly for threading and it has required the writing of mach4 to try to resolve the problems. but dont rush out and buy mach4 i'm not sure they have it working yet either . I read their yahoo group daily and see nothing about threading on the lathe yet.

the longer the thread is and the greater the pitch the greater the chance of mach3 making a mistake, at this point i'm having good results at 3 inches of threads at 8 threads per inch turning 100 rpm.

shield all your input wiring, ground the shield only on one end at the controller.

once you have all this working then I would try connecting it to your pfd

trying to do them both at the same time may cause you more problems resolving issues.

hope that helps

Steve

Issue: GekoG540. I have a regular ol' Opto Switch currently installed w/ reflective tape on the lathe pully. This setup also requires yet another 5v power supply. The design is setup to put the signal into pin 1 of the G540. It does not seem to be working. (Checking on my OScope). Before I go and mess with an Opto setup, Does anyone have a preference? Opto's -vs- Proximity's rated?

I read about how slow opto's are and on the flip side, the proximity's are rated in how fast they can run?

Q1) Is there anything in all this for a simple MAch3 turn setup? No need for overkill, but we would like to be more accurate than less and none of these seem all that expensive.

Q2) I read the G540 inputs are internally pulled to +12V and trigger as edge low as an input? But I am still just picking notes here and there off forums. Do we have some specifics about the G540 inputs and are folks using them as Vcc for the opto-transistor switch? Someone have something elegant for a pulse here off the pulley?

The setup that came w/ my unit has: 1- 220Ohm resister on the Vcc side of the emitter diode. On the transistor (pulse out) they had emitter to ground and collector to Pin 1 on the Gecko.

anyway- Before I go change this up and even bother with it.... What's out there as a quick hit, bolt and go. For 5-10 bucks I just do not have the time to play with so many projects going on.

Some sample optek circuits. ( I have a few optek sensors I bought to do the Mill spindle so I can experiment). Here are the 2 designs - common collector and common emitter outputs. Thought I would pass on the info. It's a good PDF for simply photo on/off stuff.

http://optekinc.com/pdf/app bulletin 213-opto assemblies.pdf

Anyway, Thanks as always- time to learn the lathe and get into turning!

From Jumps4: Mach3 version specific for RPM and turn to do threads:

in mach3 turn threading can only be done on a breakout board using a parallel port as far as I know. a uc100 usb will not work and I'm not sure any other usb or ethernet cards thread.

mach3 needs to be an older version the latest version does not work ( I'll try to see what version I'm running and send it to you )

pins 10,11,12,13 and 15 are input pins on the breakout board, use what ever one your not using for homing and limit swiches that is left. and on the configuration input screen set that breakout board pin number as the "index"

you can only use one pulse per revolution.

here is a good mach3 pdf to help you out ( http://www.machsupport.com/wp-content/uploads/2013/02/Mach3_Threading.pdf )

threading works best a low speed in mach3 usually not above 150

other people have other results but mach3 turn has never worked correctly for threading and it has required the writing of mach4 to try to resolve the problems. but dont rush out and buy mach4 i'm not sure they have it working yet either . I read their yahoo group daily and see nothing about threading on the lathe yet.

the longer the thread is and the greater the pitch the greater the chance of mach3 making a mistake, at this point i'm having good results at 3 inches of threads at 8 threads per inch turning 100 rpm.

shield all your input wiring, ground the shield only on one end at the controller.

once you have all this working then I would try connecting it to your pfd

trying to do them both at the same time may cause you more problems resolving issues.

hope that helps

Steve