- Joined

- Jul 28, 2017

- Messages

- 2,565

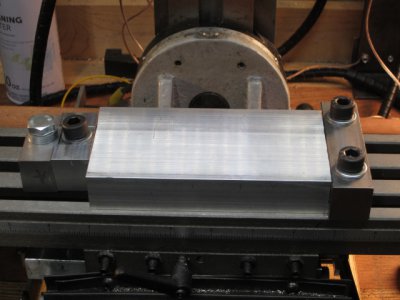

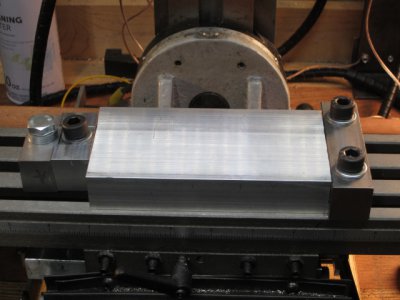

I finished up some low-profile workholders for my mill today. They are based on another H-M thread here, started by @Janderso . I liked the idea, a lot, so decided to make some for myself -- but, of course, "customizing" them according to my tastes.

Here's a photo sowing both sides.

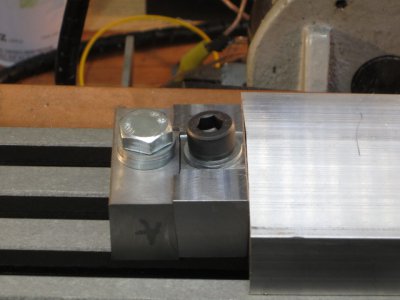

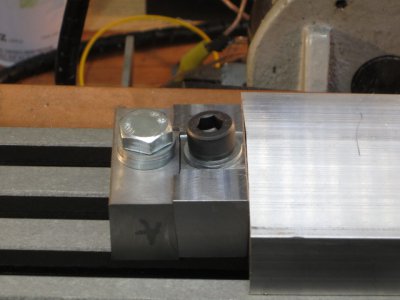

And a photo of the moveable "jaw" of the setup:

The aluminum bar is just there to show how it works. The two-piece movable jaw has the same 5 degree taper as described in the link I provided above. The right-hand component is drilled at a 5 degree angle because I thought that would produce a bit more mechanical advantage because the screw is oriented parallel to the taper angle -- it won't apply any force to the fixed side to increase any frictional load. I thought I was being original but closer examination of a similar low profile clamp design on Harold Halls's web site showed he had done the same thing. Nothing new under the sun, huh. BTW, I made tee nuts with a matching 5 degree angle so the clamping load was evenly distributed across the table.

But I didn't machine dovetails, just a simple slot and boss arrangement. I didn't think the added machining complexity was needed, considering what the clamps are for. Plus, it took a lot less time to make them compared to two dovetails.

The 5 degree angle has a huge mechanical advantage. It feels like it should be able to apply a very high clamping force.

Here's a photo sowing both sides.

And a photo of the moveable "jaw" of the setup:

The aluminum bar is just there to show how it works. The two-piece movable jaw has the same 5 degree taper as described in the link I provided above. The right-hand component is drilled at a 5 degree angle because I thought that would produce a bit more mechanical advantage because the screw is oriented parallel to the taper angle -- it won't apply any force to the fixed side to increase any frictional load. I thought I was being original but closer examination of a similar low profile clamp design on Harold Halls's web site showed he had done the same thing. Nothing new under the sun, huh. BTW, I made tee nuts with a matching 5 degree angle so the clamping load was evenly distributed across the table.

But I didn't machine dovetails, just a simple slot and boss arrangement. I didn't think the added machining complexity was needed, considering what the clamps are for. Plus, it took a lot less time to make them compared to two dovetails.

The 5 degree angle has a huge mechanical advantage. It feels like it should be able to apply a very high clamping force.