- Joined

- Nov 14, 2014

- Messages

- 851

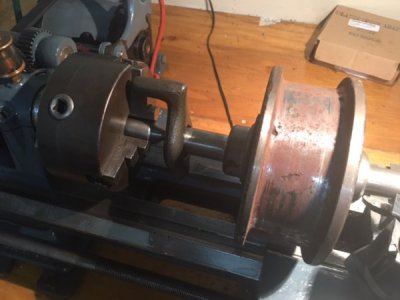

here are a few pics of my Dalton rebuild. The machine is a lot 5, SN:340. Made around 1920. I think it has been in light duty service here in the Pacific Northwest, probably in a backyard machinist shop out in the Skagit valley, since new. So not very worn. Actually very tight, with very little wear on the ways.

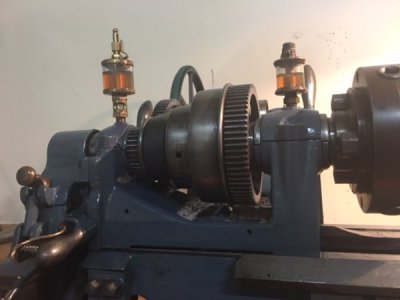

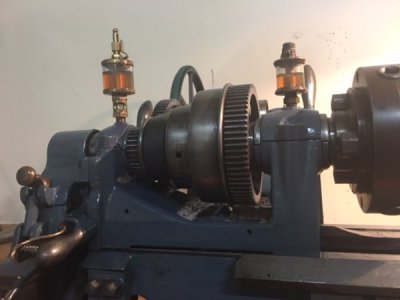

I stripped it down, repainted everything, and scrapped and shimmed the bearings in the headstock when reassembling. Got the required > .002" of movement in the headstock bearing, which was nice. (Oil fills the clearance and lubes the split bearings, hence the desired .002" of clearance).

The gears were in good shape- look new actually, with no discernible wear.

The lathe also came with a nice steady rest and a decent 3 jaw chuck.

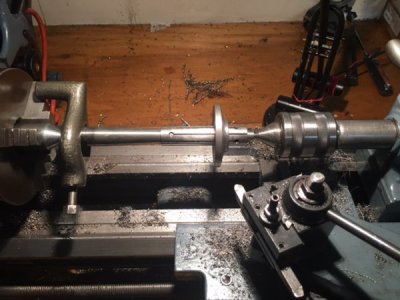

The major upgrades I added included a small quick change tool post, shimmed to place the QCTP holder at the correct height above the compound slide; new headstock and tailstock MT 2 live center, and drill chuck, and a 4" four jaw chuck. So far don't have a backing plate for the chuck or dog plate to drive work on centers. I did pick up several old Atlas 1" x10 backing plates which I intend to bore out to 1 1/4" x12 so as to fit the Dalton spindle. Then should be pretty well tooled up.

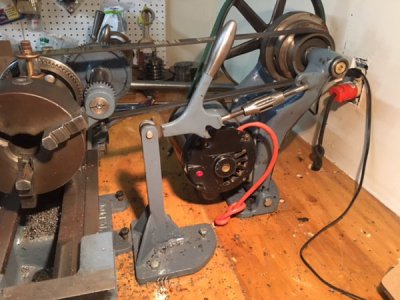

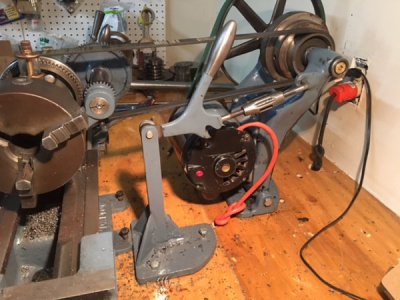

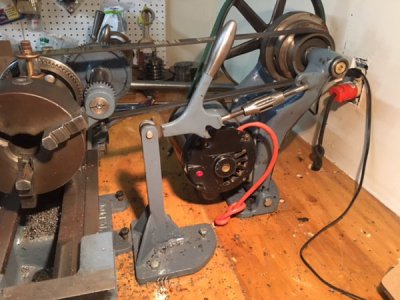

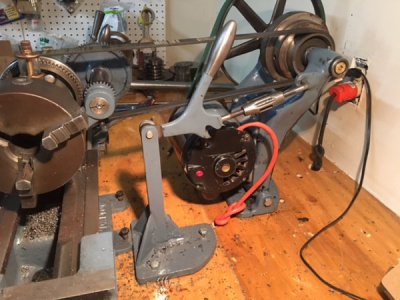

I did purchase a SB 9" countershaft assembly to mount up a motor. Pictures show the tensioning anchor I made up in lieu of the SB bolt to bed method.

So far, real happy with the result. I intend to use the lathe to make smallish parts that would be difficult to handle on my 14" south bend.

Glenn

I stripped it down, repainted everything, and scrapped and shimmed the bearings in the headstock when reassembling. Got the required > .002" of movement in the headstock bearing, which was nice. (Oil fills the clearance and lubes the split bearings, hence the desired .002" of clearance).

The gears were in good shape- look new actually, with no discernible wear.

The lathe also came with a nice steady rest and a decent 3 jaw chuck.

The major upgrades I added included a small quick change tool post, shimmed to place the QCTP holder at the correct height above the compound slide; new headstock and tailstock MT 2 live center, and drill chuck, and a 4" four jaw chuck. So far don't have a backing plate for the chuck or dog plate to drive work on centers. I did pick up several old Atlas 1" x10 backing plates which I intend to bore out to 1 1/4" x12 so as to fit the Dalton spindle. Then should be pretty well tooled up.

I did purchase a SB 9" countershaft assembly to mount up a motor. Pictures show the tensioning anchor I made up in lieu of the SB bolt to bed method.

So far, real happy with the result. I intend to use the lathe to make smallish parts that would be difficult to handle on my 14" south bend.

Glenn

Last edited:

Actually have a very interesting collection of old steam locomotives and rolling stock from the turn of the century set up as an out door museum at their depot just outside Eva. Makes a nice outing...

Actually have a very interesting collection of old steam locomotives and rolling stock from the turn of the century set up as an out door museum at their depot just outside Eva. Makes a nice outing...