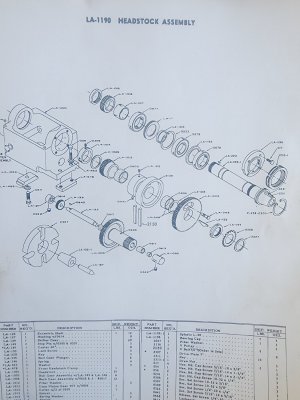

I tried to install the new spindel take up nut and found the threads to be too damaged. So I have a good used spidel coming. But this morning I pulled the pin on the bull gear so I can rotate the spindel really easy. The bearings may be shot. Really noisy. Belts are old too so maybe replace them too. Gee what fun.

What's the easy way to replace Bearings if needed and the belts? I know the spindel has to come out. Any suggestions appreciated.

Mike

What's the easy way to replace Bearings if needed and the belts? I know the spindel has to come out. Any suggestions appreciated.

Mike