My iGaging digital level isn't reliable to much better than .5º. A carpenter's spirit level is just as accurate. Ni ether is very much use for leveling a lathe for the purpose of removing twist.

@WobblyHand is correct regarding the causes of turning a taper and the process of minimizing the same.

First off, the tailstock is not involved when trying to remove a taper caused by one of the above . A tailstock. aside from support of the work, is used to intentionally introduce a taper and, as such, can be used to correct a taper. Checking for bed twist using the two collar method must be done without the aid of the tailstock.

The first thing that I would do would be to place the lathe on a reasonably flat surface totally unfastened or at a minimum with the tailstock end unfastened. This will tend to eliminated any bed twist caused by forcing the lathe to conform to an uneven surface. I would check for the ability to cut a flat face by facing a disk located as close to the headstock as possible. Working close to the headstock minimizes the effect from any bed twist so the primary cause of failure in this test is headstock misalignment. Some lathes are not capable of changing headstock alignment and any misalignment would have to be corrected for by twisting the bed. (sometimes two wrongs can make a right).

The next step is to deal with bed twist. To do this, the headstock end is firmly fastened to the surface. The tailstock end is lightly fastened as well. There are two methods of checking for taper; the two collar method and the RDM method (Rollie''s Dad's Method). My preference is the latter. For the two collar method, a rigid bar is mounted in the chuck,

unsupported by the tailstock, and a collar is turned close to the headstock and a second at the far end of the bar. A micrometer is then used to measure the turned diameters to determine taper. It is a definitive test as youe are actually measuring the defect you are trying to minimize but has some pitfalls, mainly that the bar can flex when turning so a rigid bar is required and light spring cuts must be used for the final cuts to avoid deflection buy the cutting tool. The RDM method doesn't require turning and only the force created by the dial indicator or dial test indicator figure in so bar rigidity isn't as critical. You are making four measurements rather than two and more than likely not using an indicator capable of measuring to a tenth so it is potentially less accurate. It is more convenient however as no cutting is involved, any runout in the mounting doesn't enter in to the test, and the same bar can be used many times. I do a two collar test as the final test to check my alignment.

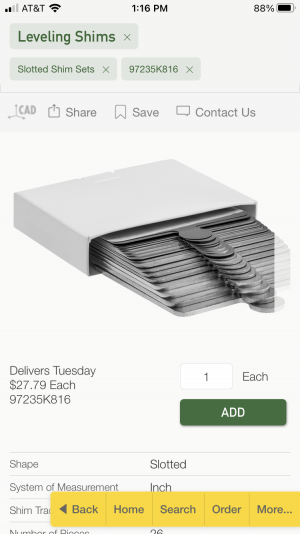

Assuming that the two collar test or the RDM test shows a misalignment, the method of correction is to shim or otherwise elevate the tailstock feet. If the tailstock diameter is smaller than the headstock diameter, the carriage is closer to the work and the bed needs to be twisted to move the carriage further from the spindle.axis. This is done by shimming the back feet appropriately. If the taper is larger at the tailstock, the bed must be twisted so the carriage is closer to the work so shims should be placed under the front feet. In either case a shim would be put in place and the mounting tightened and another test done. This process is repeated until the taper is removed to your satisfaction.

A few things to note. Twisting a lathe bed to remove taper puts a load on the 4mounting surface. A less than rigid mounting surface will flex as well and the effects of shimming may be not as great as one would expect. To add to the mix, environmentally unstable surfaces can change their shape with both temperature and humidity. For this reason, I prefer to mount to metal rather than wood. If I had to mount on wood, I would fasten the lathe just enough to prevent movement during use with the tailstock fastened to just snug. Another consideration is wear of the ways on the lathe bed. Another consideration is the lathe stand itself. It must be sturdy and stable enough to not shift or deform. Otherwise all your hard weork becomes meaningless. Finally, used lathes often have considerable wear in the regions most commonly used and any alignment will necessarily be a compromise.