- Joined

- Jun 12, 2018

- Messages

- 724

My table is not level. I ordered a PM 11x27 lathe that I should get sometime after Christmas this year.

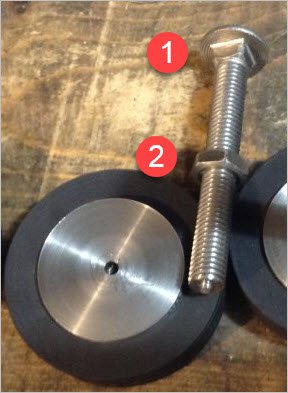

Is it a good idea to level the lathe itself instead of leveling the table? In order for me to level the table, i'd have to redo it from the ground up. It'd be easier for me to level the lathe itself. I'm trying to come up with leveling feet ideas for my lathe. I figure it'd be a lot better than shimming.

Another issue is that machinists' levels are super expensive. I'll probably just use a digital level for now and make sure the ways are level on the Y axis on both ends of the ways. I hear the X axis isn't important at all as it's not twisted the bed.

I want to be have less than .001 difference in diamater of whatever I'm turning on each end.

Anyone have a Precision Matthews 11x27?

Is it a good idea to level the lathe itself instead of leveling the table? In order for me to level the table, i'd have to redo it from the ground up. It'd be easier for me to level the lathe itself. I'm trying to come up with leveling feet ideas for my lathe. I figure it'd be a lot better than shimming.

Another issue is that machinists' levels are super expensive. I'll probably just use a digital level for now and make sure the ways are level on the Y axis on both ends of the ways. I hear the X axis isn't important at all as it's not twisted the bed.

I want to be have less than .001 difference in diamater of whatever I'm turning on each end.

Anyone have a Precision Matthews 11x27?