-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let's see your restorations.

- Thread starter repauli1

- Start date

4

4GSR

Forum Guest

Register Today

Is there a reason for painting the Bridgeport white and not gray as the lathe?

Yeah, I know, its a dumb question.

Yeah, I know, its a dumb question.

B

Bill Gruby

Forum Guest

Register Today

I can't remember the dates Ken, but there were White Bridgeports at some time. We had two at GM.

"Billy G"

"Billy G"

- Joined

- Nov 14, 2014

- Messages

- 851

Here's a couple of machine tools I have been able to restore- scrape in new bearings, remake any worn parts, and new paint etc. First up, a 1919 Dalton 7x36'' lathe. Following that are a couple of shots of my 1939 Delta DP 220 drill'press. Iam cheating because I didn't restore it. My boy found it at an estate sale in like new condition earlier this year. Even has the original water transfer decals ( badges ) from the hardware store that sold it. All the shinny metal surfaces have been kept this way since 1939, by the original owner and apparently his son.

Third, sort of in the middle, is a pic of a 1950 Burke #4 horizontal mill. I restored the Burke and the Dalton Lathe over the past two years and am using them to rebuild an antique 12" ga miniature steam locomotive.

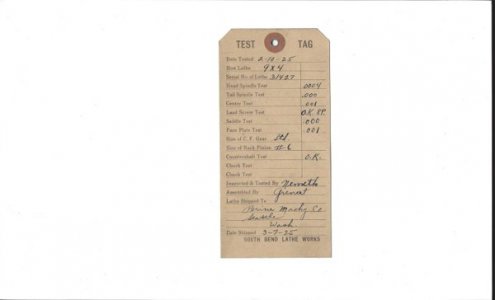

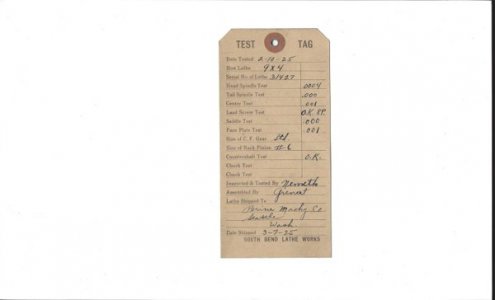

Finally couple of shots of an NOS Craigslist 1924 South Bend 9x48. Ithis one hasn't been restored yet, and I only include it because it still has original scraping on the bed, original finish, and came with the inspector's documentation card from the factory that shows the measured tolerances at final inspection! This sat on Craigslist for weeks before I noticed a hint of the scrape marks in one of the photos. Went to take a look, and couldn't believe it! Again, amazingly in nearly perfect condition, having been a hobby lathe kept in storage since 1940's. This one is awaiting some more cleaning and a T/I while I figure out how to set up a replacement drive system. Fellow I bought it from threw away the counter gear belt drive assembly years ago as it was "accumulating to many cob webs" in his garage! Arrrrrgh.

No real genius on my part. It really helps to discover old barn finds that are in really good condition to begin with. The main thing is the underlying precision needs to be there. Makes the rebuild and finish work worthwhile.

Anyway, I enjoy working with old equipment. Very satisfying when they are cleaned up and perform well.

Third, sort of in the middle, is a pic of a 1950 Burke #4 horizontal mill. I restored the Burke and the Dalton Lathe over the past two years and am using them to rebuild an antique 12" ga miniature steam locomotive.

Finally couple of shots of an NOS Craigslist 1924 South Bend 9x48. Ithis one hasn't been restored yet, and I only include it because it still has original scraping on the bed, original finish, and came with the inspector's documentation card from the factory that shows the measured tolerances at final inspection! This sat on Craigslist for weeks before I noticed a hint of the scrape marks in one of the photos. Went to take a look, and couldn't believe it! Again, amazingly in nearly perfect condition, having been a hobby lathe kept in storage since 1940's. This one is awaiting some more cleaning and a T/I while I figure out how to set up a replacement drive system. Fellow I bought it from threw away the counter gear belt drive assembly years ago as it was "accumulating to many cob webs" in his garage! Arrrrrgh.

No real genius on my part. It really helps to discover old barn finds that are in really good condition to begin with. The main thing is the underlying precision needs to be there. Makes the rebuild and finish work worthwhile.

Anyway, I enjoy working with old equipment. Very satisfying when they are cleaned up and perform well.

Last edited:

- Joined

- Feb 2, 2016

- Messages

- 55

- Joined

- Apr 24, 2017

- Messages

- 7

I was originally this color (Almond)Is there a reason for painting the Bridgeport white and not gray as the lathe?

Yeah, I know, its a dumb question.

- Joined

- Apr 24, 2017

- Messages

- 7

Great restores!Here is my Sheldon Lathe

View attachment 232417 View attachment 232418

and Van Norman 12

View attachment 232419 View attachment 232420

- Joined

- Apr 12, 2011

- Messages

- 3,573

Here is my Bridgeport.

http://www.hobby-machinist.com/threads/1958-bridgeport-series-1-j-rebuild.1442/

Here is my Ellis band saw.

http://www.hobby-machinist.com/threads/ellis-1100-bandsaw-restoration-and-modifications.20460/

http://www.hobby-machinist.com/threads/1958-bridgeport-series-1-j-rebuild.1442/

Here is my Ellis band saw.

http://www.hobby-machinist.com/threads/ellis-1100-bandsaw-restoration-and-modifications.20460/

4

4GSR

Forum Guest

Register Today