- Joined

- Oct 16, 2017

- Messages

- 341

I took a scrap block of aluminum and squared it up on the mill and found center. Then spotted and drilled a 1/2" blind hole for the arbor. Without changing the Y axis I flipped the block in the vice and marked the reference line along the X axis with a carbide tipped scribe. I then turned the pin on the 1" OD arbor and pressed it into the aluminum block (snug).

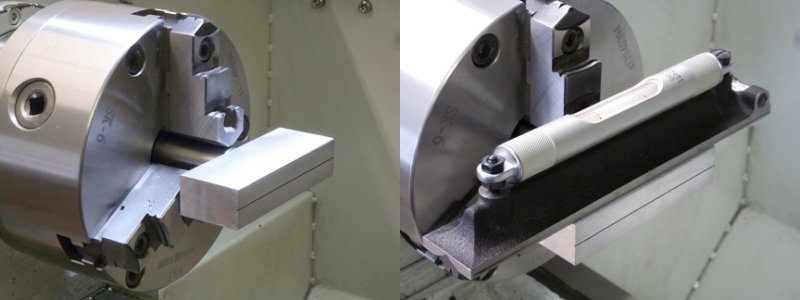

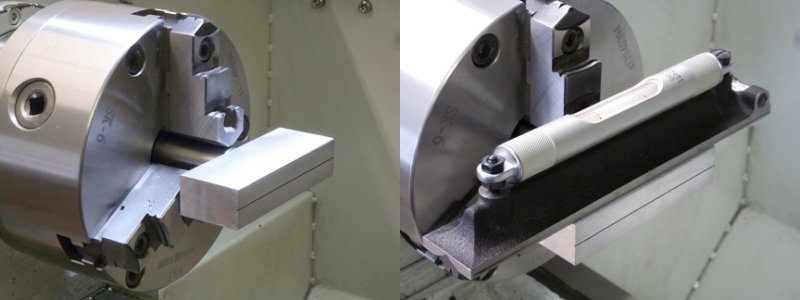

Installed in the chuck and then leveled.

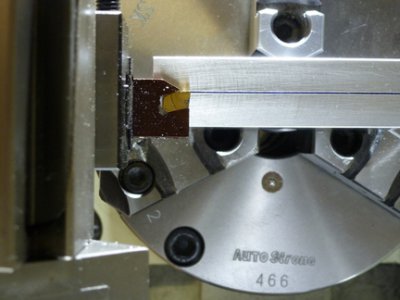

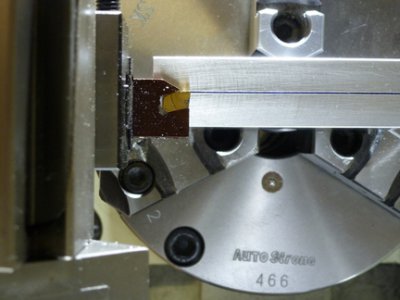

I think this approach works well for negative rake insert tooling. It is also helpful when setting a tool slightly above or below center. The obvious disadvantage is you can't check tool height with work in the chuck.

Total Cost: $1.69

Installed in the chuck and then leveled.

I think this approach works well for negative rake insert tooling. It is also helpful when setting a tool slightly above or below center. The obvious disadvantage is you can't check tool height with work in the chuck.

Total Cost: $1.69