- Joined

- Jun 12, 2014

- Messages

- 5,068

I was thinking of making some form of tapping and die clutch system for the tailstock in my lathe, where one can adjust the tapping tension so it would release at a given tension. Quite often one is either tapping either under power into a blind hole and when you get to the bottom of the hole it was not fun to have the tap holder flying around or breaking a tap. I already had a sliding tap holder, so I came up with an adjustable tension system that used some bellevue washers as both tension and allow adjustable slippage. The bellevue washers are 1" ID and 2" OD, I also purchased some uxcell T101/904A1 Thrust Tapered Roller Bearings 1.01" Bore 2" O.D. 0.625" Width that is used to prevent the handle hub to spinning the tensioning locking rings. The tapping clutch system slides on a 5/8" rod with a MT3 tailstock end. The handle hub slides on a 1" body which is threaded at the end for the tension locking rings. The tapping body accepts different adjustable taping chucks as well as round die holders, which are locked into the end with a 3/8-24" set screw.

I used materials that I had laying around, some 2" steel 1144 rod for the body/locking rings, 2.5" steel 4140 rod for the handle hub and O1 for the tap handles.

Parts and high tech drawing.....

Trust bearing bearing was pressed into to tapping handle hub.

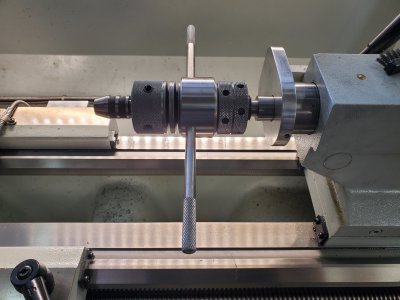

Assembled clutched tap and die holder.

Mounted to tailstock, easy to adjust the tension by holding the front body and twisting the locking rings, the thrust bearing prevents the handle hub from turning the locking rings. I went with two locking rings as an additional safety precaution to prevent the tension from changing once locked together.

I used materials that I had laying around, some 2" steel 1144 rod for the body/locking rings, 2.5" steel 4140 rod for the handle hub and O1 for the tap handles.

Parts and high tech drawing.....

Trust bearing bearing was pressed into to tapping handle hub.

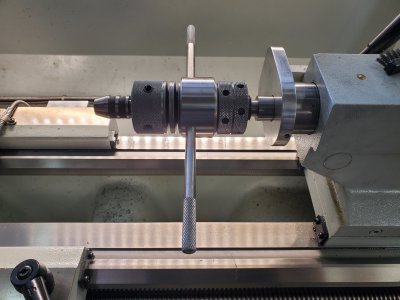

Assembled clutched tap and die holder.

Mounted to tailstock, easy to adjust the tension by holding the front body and twisting the locking rings, the thrust bearing prevents the handle hub from turning the locking rings. I went with two locking rings as an additional safety precaution to prevent the tension from changing once locked together.