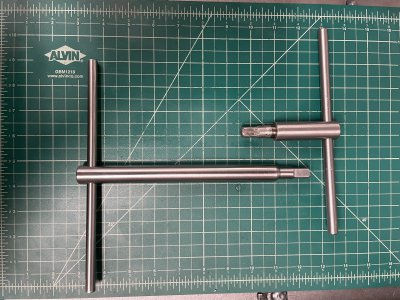

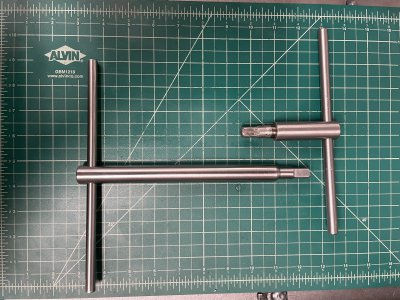

Spent some time on a couple of things I've been meaning to do ever since buying this 8" Bison Set-Tru chuck. It's a great quality, very accurate chuck, but the key that comes with them is about useless. It's only about 3-1/2"-4" long, and if you have any large diameter parts in the chuck, it's a knuckle buster. Picked through the scraps/cut offs, and made a new one. Basically a piece of 3/4" o.d. .083" wall 4130 tube, and a couple of nubs machined out of 4140 bar, pressed and welded into each end. T-handle is 3/8" drill rod. Light, comfortable, and will clear any workpiece my 14" lathe will swing.

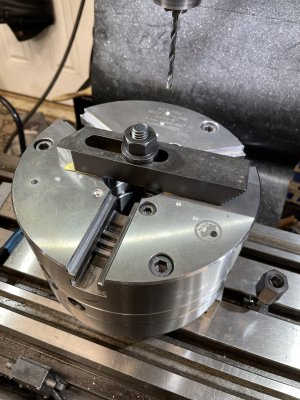

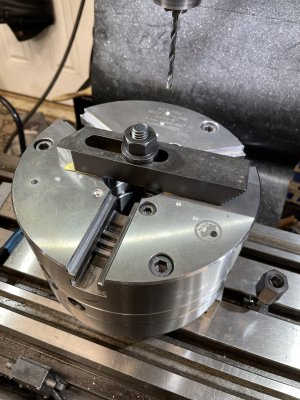

While the chuck was getting attention, I went ahead with drilling & tapping( 1/4-20 and .625" deep ) 9 holes in the face, so that sacrificial aluminum ferrules can be screwed to the chuck, and faced off, to aid in turning parts that require them having very parallel faces. Decided to go with the method Joe Pie demonstrated on his channel.

It was simple and quick to do. While it lacks the sophistication of ROBRENZ and Stefan's adjustable setups, this way is simple, cheap, and the parts won't know the difference.

While the chuck was getting attention, I went ahead with drilling & tapping( 1/4-20 and .625" deep ) 9 holes in the face, so that sacrificial aluminum ferrules can be screwed to the chuck, and faced off, to aid in turning parts that require them having very parallel faces. Decided to go with the method Joe Pie demonstrated on his channel.