- Joined

- Jan 22, 2017

- Messages

- 90

Dear All,

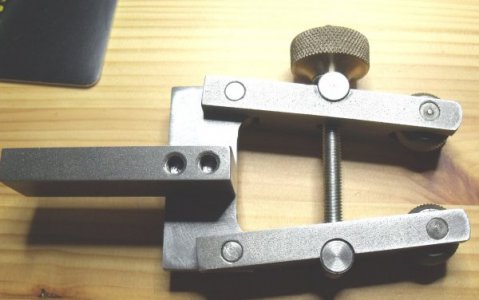

I have decided to give knurling a try and I bought a six wheel knurling tool on eBay.

Now that it has arrived, I see that it is designed for a Myford (small hobby lathes, very popular in the UK) and the shank of the tool is nearly 9/10". Now, the standard tool holder on a Myford is no more than 1/2" so, am I correct in assuming that it is designed to go in the rear tool holder?

I don't have a rear tool holder, but I can make one. However, is it worth the effort? Is a rear tool holder more rigid? If it doesn't matter, should I simply try to mill the shank down to fit my front tool holder? (I have some carbide end mills and cutters which should do the job, if I go slowly).

My gut feeling is that it would be more fun and less destructive to make a rear tool holder, which I could also use for parting off. But, it would still mount on the cross-slide, so would it be any better than using the existing front tool post?

Or should I try to make a really rigid tool holder which would mount directly on the ways?

All advice and experience gratefully received.

Kind wishes,

Nick

I have decided to give knurling a try and I bought a six wheel knurling tool on eBay.

Now that it has arrived, I see that it is designed for a Myford (small hobby lathes, very popular in the UK) and the shank of the tool is nearly 9/10". Now, the standard tool holder on a Myford is no more than 1/2" so, am I correct in assuming that it is designed to go in the rear tool holder?

I don't have a rear tool holder, but I can make one. However, is it worth the effort? Is a rear tool holder more rigid? If it doesn't matter, should I simply try to mill the shank down to fit my front tool holder? (I have some carbide end mills and cutters which should do the job, if I go slowly).

My gut feeling is that it would be more fun and less destructive to make a rear tool holder, which I could also use for parting off. But, it would still mount on the cross-slide, so would it be any better than using the existing front tool post?

Or should I try to make a really rigid tool holder which would mount directly on the ways?

All advice and experience gratefully received.

Kind wishes,

Nick