- Joined

- Dec 18, 2019

- Messages

- 7,429

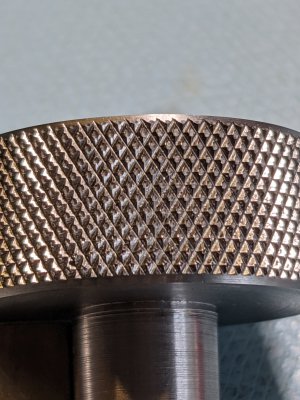

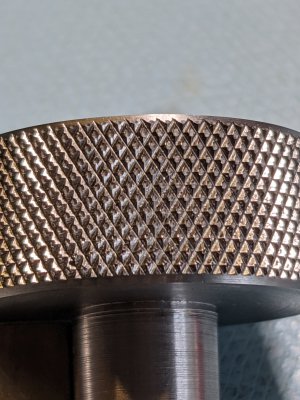

So mostly finished making my copy of @mikey 's straddle knurler. Of course a knurler deserves a knurled knob to adjust it. So I made one out of 1144. I used sulfur cutting oil which is kind of stinky, but it worked well. I was looking at the knurl and wondering how deep it really should be. How much of a point (or non-point) should there be? The knob I made has little craters rather than a point. Points would be uncomfortable, but what should a decent knurl look like (and maintain good knurling wheel life)?

This knurl is on 1.25" OD 1144, skimmed to remove the dull finish then knurled with a straddle knurler. Done with FORM ROL EQL 225 wheels. Do I need to apply a little more pressure? I'm obviously not going to throw out the knob, (it's perfectly useful and decent) but I'd like to know for the next knurl what to target.

This knurl is on 1.25" OD 1144, skimmed to remove the dull finish then knurled with a straddle knurler. Done with FORM ROL EQL 225 wheels. Do I need to apply a little more pressure? I'm obviously not going to throw out the knob, (it's perfectly useful and decent) but I'd like to know for the next knurl what to target.