Hello everyone!

I'm completely inexperienced with milling, but I've done a little research and I'm trying to decide between two manual mills I've found that I think meet my needs. Feel free to tell me if I'm way off-base; I don't know what I don't know.

To summarize my answers to the questionnaire, I think I'm looking for a little better than bottom-of-the-barrel benchtop model due to the size of the stock I anticipate working with. The two models I'm looking at are the LittleMachineShop 4190 and the Weiss VM18L-DRO. I would post links, but I don't believe I'm supposed to as a brand new forum member. The info on the Weiss I found on Toolots's website.

Based on my limited understanding, the biggest differences I notice are that the LMS has a 3-axis DRO and a 500W (~2/3HP) motor, and the Weiss has a slightly larger table, 2-axis DRO, plus electronic ruler display spindle feed and 1HP motor. So, my impressions is that the LMS might be a bit easier to work with (3-axis vs 2-axis DRO) and the Weiss has more power. I don't know if the additional power would be helpful for my use, or if the DRO difference really matters.

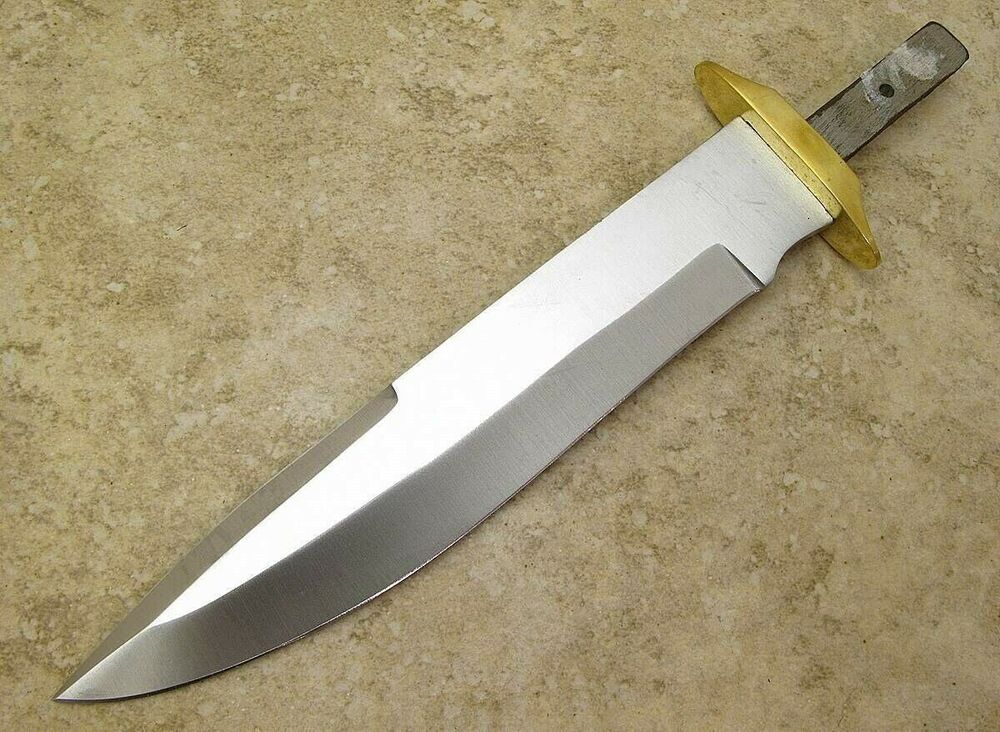

The main reason I want a mill is to more efficiently produce a crisp fit between blade and handle of a hidden tang chef knife. If you're not familiar with this, hopefully the pictures below give the general idea. It might be too much information for this post, but... I'd like to first make a slot in the handle material (around 1x1x5.5 inches of resin-stabilized wood) a couple of inches deep for the knife tang. I'm guessing that slot would likely be 1/8" or larger based on the end mills I've found so far. Second, I'd epoxy a 1x1x1/8" brass cap over the slot, and make a 3/32" wide slot, 1/8" deep to go through the brass stock. Or maybe it would be better to mill the brass first and then epoxy it to the wood, I don't know...

My steel stock is around .115" thick, so I was thinking of removing around .015-.020" from each side, so the final tang thickness would be a little under 3/32". I use steel from 52100 to high alloy stainless.

Any thoughts or suggestions on which mill would be better for my application or if I'm barking up the wrong tree would be appreciated! I imagine once I get a mill I'll find more uses for it, so aftermarket support/room for growth is relevant, but not the primary consideration.

Cheers and thanks for the help,

Eric

I'm completely inexperienced with milling, but I've done a little research and I'm trying to decide between two manual mills I've found that I think meet my needs. Feel free to tell me if I'm way off-base; I don't know what I don't know.

To summarize my answers to the questionnaire, I think I'm looking for a little better than bottom-of-the-barrel benchtop model due to the size of the stock I anticipate working with. The two models I'm looking at are the LittleMachineShop 4190 and the Weiss VM18L-DRO. I would post links, but I don't believe I'm supposed to as a brand new forum member. The info on the Weiss I found on Toolots's website.

Based on my limited understanding, the biggest differences I notice are that the LMS has a 3-axis DRO and a 500W (~2/3HP) motor, and the Weiss has a slightly larger table, 2-axis DRO, plus electronic ruler display spindle feed and 1HP motor. So, my impressions is that the LMS might be a bit easier to work with (3-axis vs 2-axis DRO) and the Weiss has more power. I don't know if the additional power would be helpful for my use, or if the DRO difference really matters.

The main reason I want a mill is to more efficiently produce a crisp fit between blade and handle of a hidden tang chef knife. If you're not familiar with this, hopefully the pictures below give the general idea. It might be too much information for this post, but... I'd like to first make a slot in the handle material (around 1x1x5.5 inches of resin-stabilized wood) a couple of inches deep for the knife tang. I'm guessing that slot would likely be 1/8" or larger based on the end mills I've found so far. Second, I'd epoxy a 1x1x1/8" brass cap over the slot, and make a 3/32" wide slot, 1/8" deep to go through the brass stock. Or maybe it would be better to mill the brass first and then epoxy it to the wood, I don't know...

My steel stock is around .115" thick, so I was thinking of removing around .015-.020" from each side, so the final tang thickness would be a little under 3/32". I use steel from 52100 to high alloy stainless.

Any thoughts or suggestions on which mill would be better for my application or if I'm barking up the wrong tree would be appreciated! I imagine once I get a mill I'll find more uses for it, so aftermarket support/room for growth is relevant, but not the primary consideration.

Cheers and thanks for the help,

Eric